The Importance of Air Compressor Tank Inspections

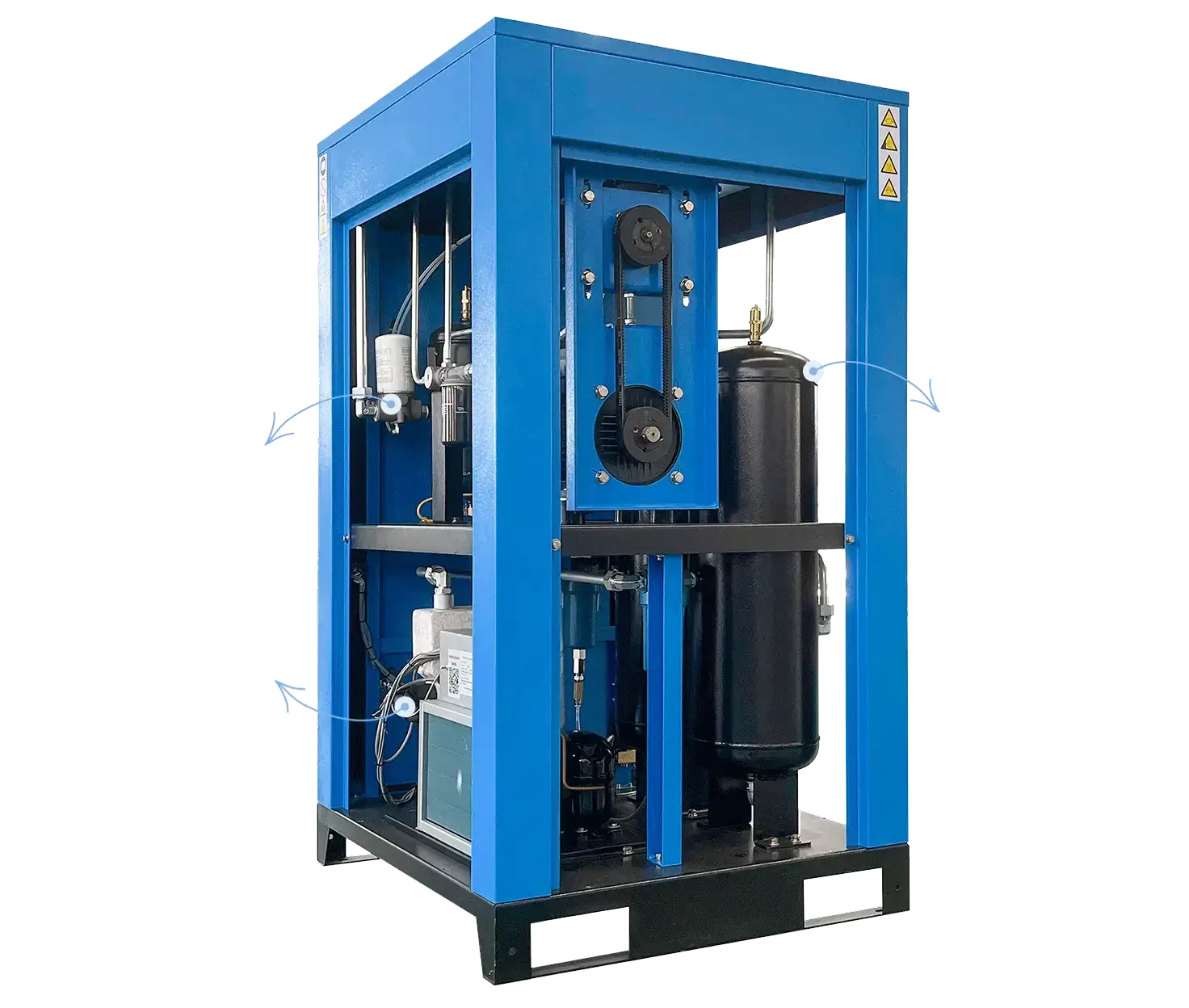

Air compressor systems serve as the backbone of countless industrial operations, powering everything from manufacturing equipment to pneumatic tools. While these systems are engineered for durability and consistent performance, they require regular maintenance and inspection to ensure safe, efficient operation.

We cannot overstate the importance of air compressor tank inspections when considering workplace safety, regulatory compliance, and operational continuity. These inspections serve multiple purposes: They identify potential safety hazards before they become dangerous, ensure compliance with federal and state regulations, and maintain optimal system performance. Professional inspection protocols are designed to detect issues such as corrosion, structural weaknesses, faulty safety devices, and pressure-related problems that could lead to catastrophic failures.

Understanding Tank Inspection Requirements

Air compressor tank inspections are governed by strict regulatory standards that vary depending on tank size, pressure ratings, and operating conditions. The Occupational Safety and Health Administration (OSHA) requires employers to ensure they keep pressure vessels in safe operating condition through regular inspections and maintenance, including air compressor tanks.

Most jurisdictions require annual inspections for tanks operating at pressures exceeding specific thresholds. Qualified personnel who are knowledgeable about pressure vessel safety standards and inspection procedures must conduct these inspections. The inspection process typically includes internal and external examinations to assess the tank’s structural integrity, the functionality of its safety devices, and its overall condition.

Many insurance companies also require documented inspection records as part of their coverage terms. Additionally, some manufacturing standards and certifications mandate regular tank inspections to maintain compliance with industry-specific requirements.

Safety Hazards Associated With Uninspected Tanks

Neglecting regular tank inspections can lead to serious safety hazards that put workers and facilities at risk. Improperly maintained pressure vessels can experience catastrophic failures, resulting in explosions, injuries, and property damage. These incidents often occur without warning, making preventive inspections essential for maintaining a safe work environment.

For example, internal corrosion can develop gradually over time, weakening the tank walls and creating potential failure points. External corrosion, while more visible, can also compromise structural integrity if left unchecked. Regular inspections can identify corrosion in its early stages, allowing for timely repairs or replacement before safety becomes compromised.

Faulty safety devices pose another significant hazard. Pressure relief valves, safety shutoffs, and monitoring systems must function properly to prevent dangerous pressure buildup. When these devices fail, tanks can exceed their safe operating pressure, creating conditions that could lead to rupture or explosion. Inspection procedures specifically focus on testing these safety systems to ensure they respond appropriately under various operating conditions.

Key Components Examined During Inspections

Professional tank inspections encompass multiple components and systems that contribute to safe operation. The tank shell receives a thorough examination for signs of corrosion, cracking, denting, or other structural damage. Inspectors use specialized equipment to measure wall thickness and identify areas where metal fatigue or deterioration may have occurred.

Compressed air tanks require careful evaluation of their internal surfaces, which you can only assess through proper entry procedures and specialized inspection techniques. Internal inspections reveal the condition of tank walls, the presence of contaminants, and the effectiveness of moisture control systems. These examinations often uncover issues that are not visible from external inspections alone.

Inspectors test pressure relief valves and safety systems at various pressure levels to ensure they activate at the correct pressure settings and provide adequate protection. This testing process identifies devices that may have become stuck, corroded, or otherwise compromised.

Mounting systems, support structures, and connections must also support the tank’s weight and withstand the stresses associated with pressure cycling. Loose mountings or degraded support structures can lead to excessive vibration, stress concentrations, and potential failure points.

Inspection Procedures and Methodologies

Professional tank inspections typically begin with a review of the tank’s operating history, maintenance records, and any previous inspection findings. This information helps inspectors focus on areas of concern and track the progression of any identified issues.

External inspections involve visual examination of the tank exterior, including the shell, heads, nozzles, and attachments. Inspectors look for signs of corrosion, damage, leakage, or other abnormal conditions. Non-destructive testing methods, such as ultrasonic thickness measurements, may be used to assess wall thickness and identify areas of concern.

Internal inspections require the tank to be taken out of service, drained, and properly prepared for entry. This process involves specific safety procedures to ensure inspector safety and prevent contamination.

Inspectors may conduct pressure testing as part of the inspection process, particularly when structural concerns are identified. These tests verify the tank’s ability to safely contain pressure and identify any weaknesses that may not be apparent during visual examination.

Frequency and Scheduling Considerations

The frequency of tank inspections depends on several factors, including tank size, operating pressure, service conditions, and regulatory requirements. Most facilities schedule annual inspections for tanks operating above specific pressure thresholds, while tanks in severe service conditions may require more frequent examination.

Scheduling inspections requires careful coordination with production schedules to minimize operational disruption. Many facilities schedule inspections during planned maintenance shutdowns or periods of reduced production. This approach allows adequate time for thorough inspection and any necessary repairs without impacting normal operations.

Emergency inspections may be necessary when operational problems or safety concerns arise. These unscheduled inspections identify immediate hazards and determine appropriate corrective actions. Establishing relationships with qualified inspection services helps ensure a rapid response when emergency inspections become necessary.

Maintaining Inspection Records and Documentation

Proper documentation of inspection activities is essential for regulatory compliance and effective maintenance management. Inspection records should include detailed findings, photographs of any issues identified, and recommendations for corrective actions. These records serve as legal documentation of compliance efforts and provide valuable information for future inspections.

Digital record-keeping systems help organize inspection data and make it easily accessible for review by inspectors, maintenance personnel, and regulatory authorities. These systems can track inspection schedules, maintain historical data, and generate reports that identify trends or recurring issues.

Regular review of inspection records helps identify patterns that may indicate systemic problems or opportunities for improvement. This analysis can lead to modifications in operating procedures, maintenance practices, or system design that enhance safety and reliability.

Choosing Qualified Inspection Services

Selecting qualified inspection services is crucial for ensuring thorough, accurate inspections that meet regulatory requirements. Qualified inspectors possess the necessary training, certification, and experience to evaluate pressure vessels and identify potential safety hazards properly.

When evaluating inspection services, consider the inspector’s qualifications, experience with similar systems, availability for emergency inspections, and the quality of the inspection reports. Reputable inspection services maintain current certifications, use appropriate inspection equipment, and provide detailed documentation of their findings.

Long-term relationships with qualified inspection services often result in better service quality and more consistent inspection procedures. These relationships enable inspectors to become familiar with specific systems and operating conditions, resulting in a more effective identification of potential problems.

Act on Your Air Compressor Safety

Now that you know the importance of air compressor tank inspections, you can see why they represent a fundamental responsibility for any facility operating compressed air systems. These inspections protect workers, ensure regulatory compliance, and maintain the system’s reliable operation. The comprehensive nature of professional inspections provides valuable information that supports effective maintenance planning and helps prevent costly equipment failures.

Establishing a regular inspection schedule with qualified professionals demonstrates a commitment to safety and regulatory compliance. This proactive approach identifies potential problems before they become serious hazards, ultimately protecting both personnel and equipment investments.