Pure Performance with Oil-Free Air Compressors

Air Purity You Can Trust — Zero Oil, Zero Compromise.

Difference with Oil Free Solutions

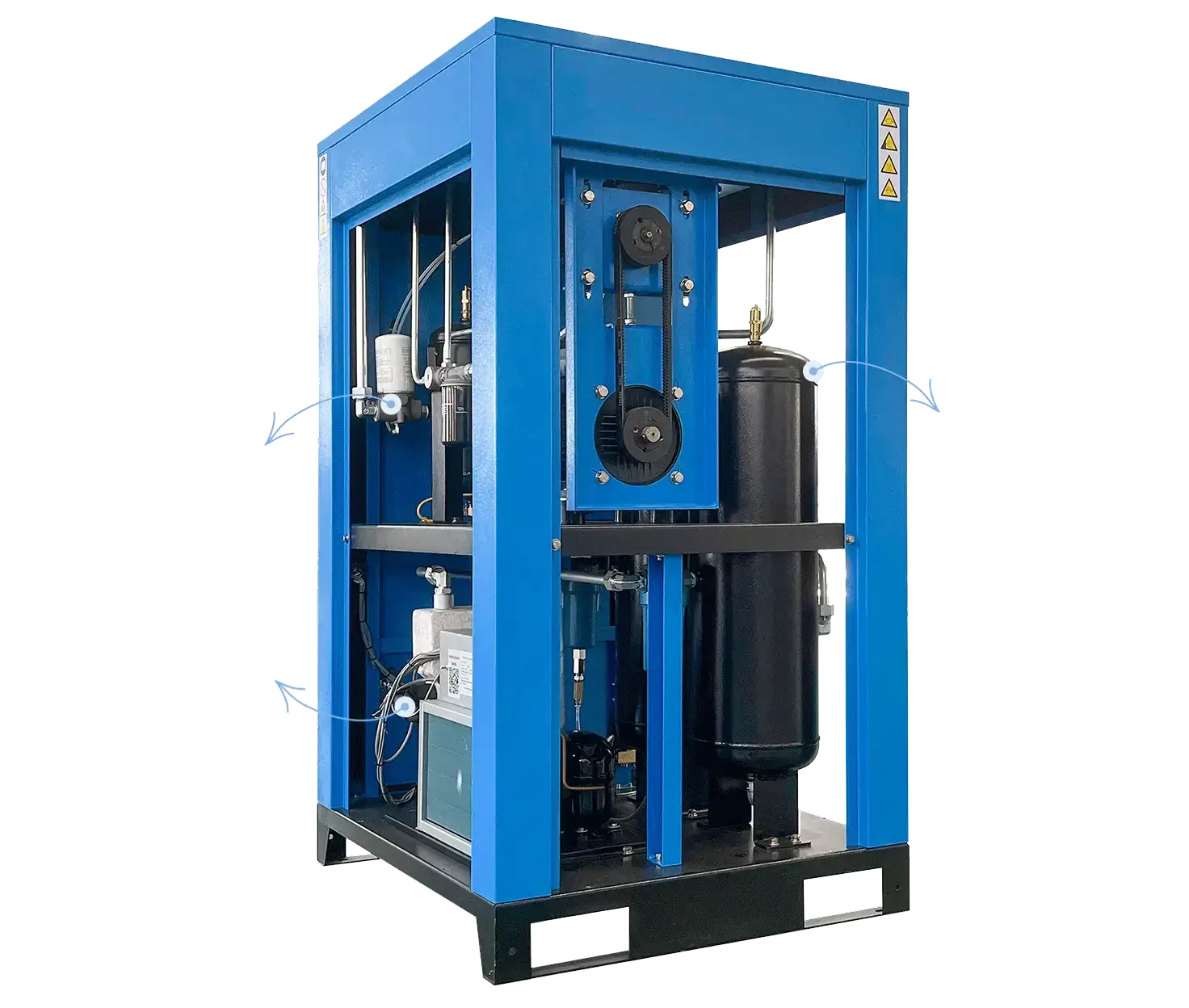

Oil Free Scroll Air Centers

An oil-free scroll air center (all-in-one) compressor is a compact, fully integrated compressed air system that combines an oil-free scroll compressor, air dryer, filters, and often an air receiver tank in a single, plug-and-play unit. Designed for applications requiring clean, quiet, and reliable compressed air, it provides 100% oil-free and moisture-free air with minimal footprint and simplified installation.

Oil Free Dry Compressors

An oil-free dry compressor operates without using oil for lubrication or cooling and also does not rely on injected liquids (like water or oil) during the compression process—hence the term “dry.” These compressors typically use dry-running mechanisms such as scroll, screw, piston, or centrifugal technology, with special coatings or materials to reduce friction between moving parts.

Oil Free Turbo Blowers

An oil-free turbo blower air compressor is a high-speed, dynamic compressor that uses a centrifugal impeller to generate compressed air without any oil in the compression process. It relies on air or magnetic bearings instead of traditional oil-lubricated bearings, ensuring that the entire system remains completely oil-free.

BENEFITS OF AN OIL-FREE AIR COMPRESSOR

Air purity

that meets the most stringent hygienic standards.

100% oil-free

pure compressed air that is more energy-efficient and environmentally friendly.

High-efficiency

oil-free air end and aviation-grade impeller coating ensure durability.

Unique design

and high-precision components enhance performance and service life.

Energy efficiency

through permanent magnet frequency conversion across varying operating conditions.

Independent air intake

directly absorbs external cooling air, with a large air filter box for easy filter replacement.

The silencer design

effectively reduces exhaust noise, while the integrated machine structure ensures low noise output.

Air filter

high-efficiency 3-micron air filter minimizes wear and prolongs air end life.

Oil-Free Scroll Air Center

Industries such as pharmaceuticals, food and beverage, electronics and textiles cannot risk any chance of oil contamination in their processes. Therefore, it is essential that the compressed air is 100% oil-free. The standard is ISO 8573-1 (2010) certification, in which Class Zero represents the highest air purity. It is the only way to ensure oil-free air for your critical processes and with it peace of mind.

100% Oil-Free Air

The oil free air compressor no oil to lubricated, which guarantees zero risk of oil contamination, ideal for industries like pharmaceutical,

food, and electronics.

Quiet Operation

Featuring high-efficiency IE3 motors and operating at noise levels as low as 53db, these compressors cut energy costs and ensure a quieter workspace.

Compact- Easy to Service

The vertical layout with minimal moving parts make the oil free air center easy to maintain, reducing downtime and keeping operations smooth.

Oil-Free Dry Compressor

An oil-free dry compressor is a clean, efficient, and low-maintenance solution for industries that demand uncompromised air quality and zero oil contamination, offering reliable performance with a focus on purity and environmental safety.

Complete, ready-for-operation unit

– Fully automatic operation

– Super soundproofing

– Vibration dampening

– Service-friendly design

– Operates in ambient temperatures up to 45°C

Industry-leading Original

oil-free Airend

– 100% oil-free air compression

– Lifetime compression efficiency with Ultracoat treated rotors and housing surfaces

– Prevents corrosion

– Enhances compression efficiency

– Long-lasting, heat- and pressure-resistant performance

– Stainless steel rotors in the high-pressure stage prevent corrosion

– High operational efficiency

– Reliable under the most demanding conditions

Pipe System

– Designed for optimal pressure and minimal loss

– Uses 304 stainless steel piping, resistant to corrosion under high temperature and humidity

– Long service life and improved unit efficiency

Drive motor

– Super Premium Efficiency IE4 motor

– Produced by a top-tier Chinese manufacturer

– Continuous monitoring of motor winding temperature

– Enclosure rated IP55

Cooling

– Generously sized aftercooler with stainless steel precooler and aluminum cooler

– Reliable performance up to 45°C

– Aluminum gear oil cooler

Electrical components

and VSD system

– IP54-rated control cabinet

– Ventilated switching cabinet

– Energy-saving frequency conversion system

– Special control system with multiple pressure and temperature sensors

– Full monitoring of operating status

– User-friendly interface with precise and reliable controls

Ultracoat

Ultracoat is essential for our oil-free compressors’ reliability, durability, and efficiency. It coats rotor profiles, sealing journals, housing bores, and end covers, and serves two key functions:

– Enhances efficiency, lowers discharge temperature, increases airflow, and reduces energy use.

– Provides outstanding corrosion resistance even under extreme conditions (up to 270°C).

The oil-free air end is a double-stage, gear-driven screw compressor block suitable for general industrial use.

Why choose Oil-Free Turbo Blower ?

An oil-free turbo blower air compressor is a clean, energy-efficient, and low-maintenance solution for high-flow applications where air purity and operational reliability are crucial.

Common Applications:

Wastewater treatment (aeration)

Food and beverage processing

Electronics manufacturing

Pharmaceutical production

Chemical and textile industries

100% Oil-Free Air

Delivers Class 0 certified air, ideal for industries where even trace amounts of oil can contaminate products or processes.

High Efficiency

Uses advanced impeller and motor technology (often with permanent magnet motors and variable speed drives) for excellent energy efficiency.

Low maintenance

No oil changes or complex gear systems, and fewer moving parts reduce the risk of mechanical wear.

Low Noise and Vibration

Magnetic or air bearing systems allow for near-silent, vibration-free operation.

Smart Controls

Equipped with advanced monitoring and control systems for real-time performance optimization

Oil-Free COMPRESSED AIR SOLUTION

5 HP OIL FREE SCROLL AIR CENTER Rotary Screw -VSD- Compressor With Built in Dryer And Tank Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 14 CFM @ 100 PSI / 13 CFM @ 125 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 640.00 lbs - 37/ 43/71 in | Shop Now 10833.33 USD | 12999.99 CAD |

5 HP OIL FREE SCROLL AIR CENTER Rotary Screw -VSD- Compressor With Built in Dryer And Tank Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 14 CFM @ 100 PSI / 13 CFM @ 125 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 640.00 lbs - 37/ 43/71 in | Shop Now 10833.33 USD | 12999.99 CAD |

10 HP OIL FREE SCROLL AIR CENTER Rotary Screw -VSD- Compressor With Built in Dryer And Tank Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 29.3 CFM @ 100 PSI / 28.4 CFM @ 125 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1040 lbs - 62.20/ 49/82.90 in | Shop Now 16666.66 USD | 19999.99 CAD |

10 HP OIL FREE SCROLL AIR CENTER Rotary Screw -VSD- Compressor With Built in Dryer And Tank Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 29.3 CFM @ 100 PSI / 28.4 CFM @ 125 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1040 lbs - 62.20/ 49/82.90 in | Shop Now 16666.66 USD | 19999.99 CAD |

10 HP OIL FREE SCROLL AIR CENTER Rotary Screw -VSD- Compressor With Built in Dryer And Tank Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 29.3 CFM @ 100 PSI / 28.4 CFM @ 125 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1040 lbs - 62.20/ 49/82.90 in | Shop Now 12499.99 USD | 14999.99 CAD |

Us Air Compressor experts ready to help for all your compressed air questions

We are experts in our field, and our team is ready to assist you with any specific needs you may have in making the right selection.

Trusted by industry leaders

We will reply within 24 hours