How Do Compressed Air Dryers Work? What To Know

Compressed air is vital for various industries, powering everything from manufacturing machinery to HVAC systems. Yet, your equipment’s compressed air doesn’t naturally come in a clean, dry state. It carries moisture that can lead to equipment damage, corrosion, and decreased efficiency. This is where an air dryer becomes indispensable.

This article will walk you through the core principles of how compressed air dryers work, the types of dryers, and what makes them essential in ensuring a well-functioning, efficient system.

What Is a Compressed Air Dryer?

A compressed air dryer removes moisture from compressed air. Without these dryers, the air in your compressed air system would contain high levels of water vapor, leading to condensation as the air cools. Excess moisture can compromise the integrity and performance of air tools, pneumatic systems, and other connected components.

By removing this moisture, air dryers protect equipment, improve operational efficiency, and extend the system’s life. This makes them a critical component in industries relying on compressed air.

Why Is Moisture Harmful in a Compressed Air System?

Compressed air naturally contains water vapor. When compressed, the moisture in the air reaches its dew point. If not treated, the water condenses in the pipes, tanks, and tools connected to the system.

This moisture causes serious problems, including corrosion in piping, damage to sensitive pneumatic tools, and contamination of the end product in applications like food and pharmaceutical production. Also, accumulated water can freeze in colder environments, resulting in pressure drops or even system failures.

Using a compressed air dryer eliminates these risks, ensuring that the compressed air powering your operations is dry and free of unwanted moisture that could hinder performance and damage your investments.

How Do Compressed Air Dryers Work?

While the specific mechanism varies by type, their goal is universally the same—to remove moisture after the air compression process. The following sections explain how these devices function across common types of air dryers.

Refrigerated Air Dryers

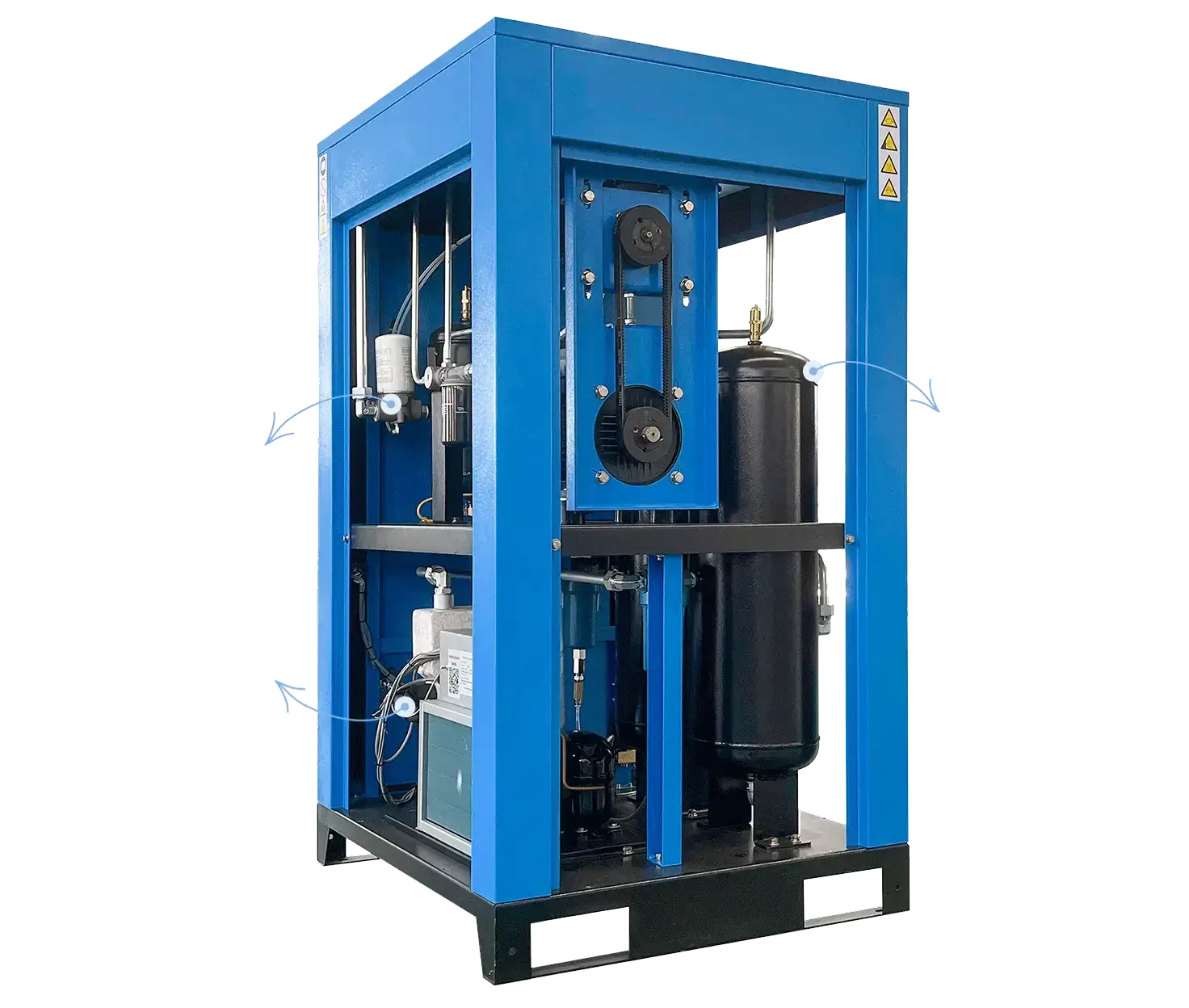

Refrigerated air dryers, commonly used for industrial applications, rely on cooling to condense moisture from compressed air. Warm, moisture-laden air enters the dryer, and the dryer rapidly cools it to a temperature where water vapor condenses into liquid form. The machine then drains this liquid away, leaving the compressed air dry before it exits the system.

This type of dryer is ideal for applications requiring a dew point of about 38 degrees Fahrenheit to 50 degrees Fahrenheit. Refrigerated dryers are a dependable and cost-effective solution but may not be suitable for environments requiring ultra-dry air.

Desiccant Air Dryers

Desiccant air dryers use a chemical desiccant material to absorb moisture from the compressed air. The air passes through a chamber filled with desiccant beads, which capture and hold the moisture. These dryers can achieve extremely low dew points, as low as -40 degrees Fahrenheit, making them an excellent choice for applications requiring ultra-dry air, such as food processing and electronics manufacturing.

Desiccant dryers typically involve a regeneration cycle to “recharge” the desiccant material, ensuring it remains effective over time. This cycle normally alternates between two desiccant chambers, maintaining continuous dry air flow.

Membrane Air Dryers

Membrane air dryers use permeable membrane technology to remove moisture from compressed air. The air goes through a bundle of hollow fiber membranes that allow water vapor to pass while retaining dry air. This makes the system energy-efficient and ideal for low-flow, portable, or remote applications.

While membrane dryers are easy to maintain, they often have limited use for applications not requiring extremely dry air, as their dew point reduction capability is moderate compared to refrigerated or desiccant options.

Deliquescent Air Dryers

Deliquescent air dryers are chemical-based and operate by dissolving water vapor into an absorbent material, such as a hygroscopic powder. This material gradually dissolves as it absorbs moisture, forming a liquid that you drain from the system.

These dryers are simple and cost-effective but require regular replenishment of the absorbent material. They are typical in low-demand applications or environments with modest drying needs.

Choosing the Right Dryer for Your Operation

Selecting the right air dryer depends on the desired dew point, operating environment, and system demands. Refrigerated dryers are for general-purpose operations, while desiccant dryers are essential for applications demanding ultra-dry air. Membrane and deliquescent dryers offer unique benefits that cater to niche applications. Assessing your needs and consulting with experts ensures you choose the most suitable option for your compressed air system.

Maintenance for Optimal Air Dryer Performance

Routine maintenance maximizes the lifespan and performance of compressed air dryers. Neglecting proper care reduces their effectiveness and may lead to costly repairs or system downtime. Regularly check for issues like clogged filters, worn seals, or improperly functioning drainage systems.

For refrigerated dryers, ensure that cooling systems operate efficiently and drain condensate regularly. Desiccant dryers require periodic replacement or regeneration of the desiccant material, along with inspection of chambers and seals.

We recommend establishing a maintenance schedule tailored to your specific equipment and applications. Partnering with professional service providers ensures that your air dryer remains reliable and performs at its best.

The Benefits of Using Compressed Air Dryers

Air dryers deliver several key advantages. Moisture removal eliminates corrosion risks, extends equipment lifespan, and ensures consistent product quality. For industries like food and beverage, pharmaceuticals, and electronics, the absence of moisture safeguards against contamination and product wastage.

Furthermore, many dryers improve energy efficiency by reducing strain on downstream equipment. Proper drying minimizes wear and tear, resulting in lower maintenance costs and improved reliability across your operation.

Investing in a high-quality air dryer enhances the overall performance of your compressed air system, providing visible benefits in operational efficiency and cost savings.

Ensuring Long-Term System Efficiency

To maintain system efficiency, consider the air dryer as one critical element in a broader approach to compressed air system optimization. Regular evaluation and upgrades to connected components, such as filters, compressors, and storage tanks, yield greater benefits over time.

Monitoring system performance and ensuring compatibility between components prevents potential mismatches that could compromise efficiency. Working closely with industry professionals allows you to leverage expert advice and tailor solutions to your unique operational needs.

Transform Your Air System With Proper Drying Solutions

Compressed air is the lifeblood of countless industries, but inadequate moisture management can jeopardize even the most robust systems. By understanding how compressed air dryers work, businesses can implement effective drying solutions that drive efficiency and reliability.

Whether you’re selecting the right dryer type or upholding a rigorous maintenance schedule, your efforts significantly enhance productivity and cost-effectiveness. Optimize your compressed air system by incorporating an air dryer, ensuring moisture doesn’t hinder operational success.