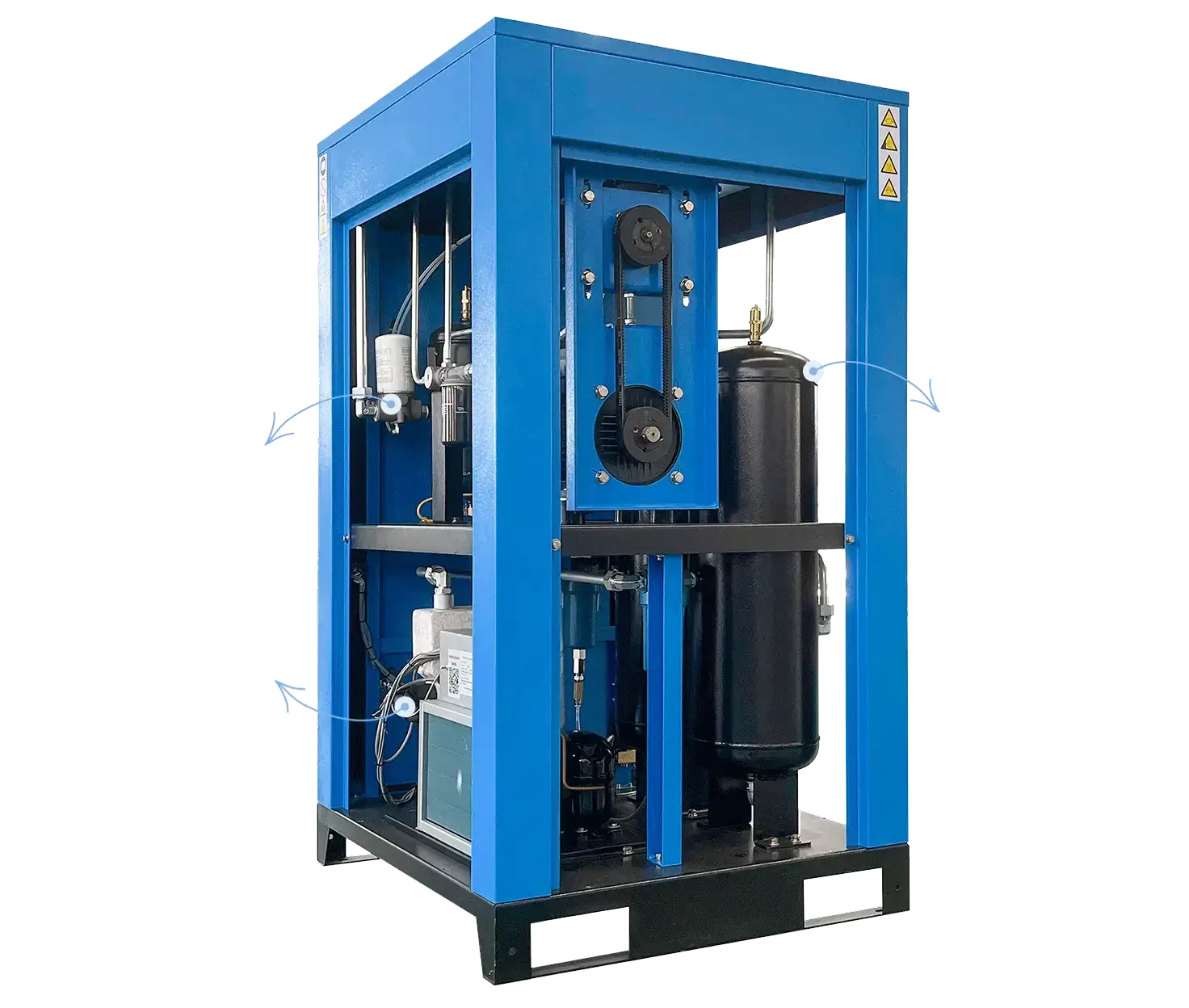

Variable-Speed Compressor

Dependable Performance With Variable Speed Drive, VSD

- 35% more Energy Saving than standard Compressor

- Designed for 24/7 workload

The world’s first Bluetooth enabled Compressor !

Why Consider a VSD Compressor?

Intelligent drive systems are used by variable speed drive (also known as variable frequency drive or regulated speed) compressors to continually adjust the motor speed to match the air demand. This drive adjusts the unit’s speed (RPM) in response to demand, varying the amount of power consumed to precisely match the output necessary. When the demand slows, the compressed air system will reduce motor speed and thus the power consumption is also reduced.

What advantages does an VSD/VFD compressor have?

- Ability to start and stop under full system pressure without the need to unload.

- Reduced power expenses – no energy loss when operating at a reduced load.

- Less power spikes – don’t activate the air compressor motor when the highest currents are present.

- Up to 35% less energy is needed than with a normal fixed speed compressor, making it more energy efficient. This makes variable-speed compressors an excellent choice for industries wanting to reduce their carbon footprint while maintaining high performance.

- Precise electrical control allows for the slackening, stopping, or acceleration of motor speeds.

- System leaks are minimized since the risk of leakage is lower with lower system pressure. The equipment reduces energy consumption and enhances system reliability through its dynamic response to air demand changes.

MORE EFFICIENT HIGHLY PERFORMANT

7 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 29 CFM @ 90 PSI / 19 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 640.00 lbs - 44.00/ 31.00/73.00 in | Shop Now 7249.99 USD | 8999.99 CAD |

10 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 43 CFM @ 90 PSI / 29 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 705 lbs - 44.00/ 31.00/73.00 in | Shop Now 7299.99 USD | 9999.99 CAD |

10 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 43 CFM @ 90 PSI / 29 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 705 lbs - 44.00/ 31.00/73.00 in | Shop Now 7299.99 USD | 9999.99 CAD |

10 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 43 CFM @ 90 PSI / 29 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 705 lbs - 44.00/ 31.00/73.00 in | Shop Now 7299.99 USD | 9999.99 CAD |

10 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 43 CFM @ 100 PSI / 25 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 506 lbs - 27.56/ 35.00/39.37 in | Shop Now 4699.99 USD | 5999.99 CAD |

10 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 43 CFM @ 100 PSI / 25 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 506 lbs - 27.56/ 35.00/39.37 in | Shop Now 4799.99 USD | 5999.99 CAD |

10 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 43 CFM @ 100 PSI / 25 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 506 lbs - 27.56/ 35.00/39.37 in | Shop Now 4799.99 USD | 5999.99 CAD |

15 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 63 CFM @ 90 PSI / 43 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 705 lbs - 44.00/ 31.00/73.00 in | Shop Now 9999.99 USD | 12999.99 CAD |

15 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 63 CFM @ 90 PSI / 43 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 705 lbs - 44.00/ 31.00/73.00 in | Shop Now 9999.99 USD | 12999.99 CAD |

15 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 63 CFM @ 90 PSI / 43 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 705 lbs - 44.00/ 31.00/73.00 in | Shop Now 9999.99 USD | 12999.99 CAD |

15 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 61 CFM @ 100 PSI / 36 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 506 lbs - 27.56/ 35.00/39.37 in | Shop Now 6999.99 USD | 8790.59 CAD |

15 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 61 CFM @ 100 PSI / 36 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 506 lbs - 27.56/ 35.00/39.37 in | Shop Now 6499.99 USD | 7999.99 CAD |

20 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 86 CFM @ 100 PSI / 57 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 950 lbs - 43.00/ 37.00/71.00 in | Shop Now 13299.99 USD | 16299.99 CAD |

20 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 86 CFM @ 100 PSI / 57 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 950 lbs - 43.00/ 37.00/71.00 in | Shop Now 13299.99 USD | 16299.99 CAD |

20 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 86 CFM @ 100 PSI / 57 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 950 lbs - 43.00/ 37.00/71.00 in | Shop Now 13299.99 USD | 16299.99 CAD |

20 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 86 CFM @ 100 PSI / 57 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 682 lbs - 40/ 31.89/42.52 in | Shop Now 8899.99 USD | 10763.99 CAD |

20 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 86 CFM @ 100 PSI / 57 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 682 lbs - 40/ 31.89/42.52 in | Shop Now 7999.99 USD | 10763.99 CAD |

20 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 86 CFM @ 100 PSI / 57 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 682 lbs - 40/ 31.89/42.52 in | Shop Now 7999.99 USD | 10763.99 CAD |

25 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 111 CFM @ 90 PSI / 79 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1660.00 lbs - 57.00/ 39.00/87.00 in | Shop Now 14299.99 USD | 19299.99 CAD |

25 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 111 CFM @ 90 PSI / 79 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1660.00 lbs - 57.00/ 39.00/87.00 in | Shop Now 14299.99 USD | 19299.99 CAD |

25 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 111 CFM @ 90 PSI / 79 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1660.00 lbs - 57.00/ 39.00/87.00 in | Shop Now 14299.99 USD | 19299.99 CAD |

25 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 115 CFM @ 100 PSI / 75 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 960 lbs - 50/ 35.83/48.43 in | Shop Now 10499.99 USD | 11279.99 CAD |

25 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 115 CFM @ 100 PSI / 75 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 960 lbs - 50/ 35.83/48.43 in | Shop Now 9199.99 USD | 11999.99 CAD |

25 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 115 CFM @ 100 PSI / 75 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 960 lbs - 50/ 35.83/48.43 in | Shop Now 9199.99 USD | 11999.99 CAD |

30 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 208-230V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 129 CFM @ 90 PSI / 96 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1100 lbs - 57.00/ 39.00/87.00 in | Shop Now 17999.99 USD | 24999.99 CAD |

30 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 129 CFM @ 90 PSI / 96 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1100 lbs - 57.00/ 39.00/87.00 in | Shop Now 17999.99 USD | 24999.99 CAD |

30 HP US AIR CENTER Rotary Screw -Variable Speed Drive- Compressor With Built in Dryer And Tank Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 129 CFM @ 90 PSI / 96 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1100 lbs - 57.00/ 39.00/87.00 in | Shop Now 17999.99 USD | 24999.99 CAD |

30 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 129 CFM @ 100 PSI / 96 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1210 lbs - 50/ 36/48 in | Shop Now 11799.99 USD | 13919.99 CAD |

30 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 129 CFM @ 100 PSI / 96 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1210 lbs - 50/ 36/48 in | Shop Now 10299.99 USD | 13919.99 CAD |

30 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 129 CFM @ 100 PSI / 96 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1210 lbs - 50/ 36/48 in | Shop Now 10299.99 USD | 13919.99 CAD |

40 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 1Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 186 CFM @ 100 PSI / 111 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1760 lbs - 58/ 37.80/50.39 in | Shop Now 15399.99 USD | 17999.99 CAD |

40 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 186 CFM @ 100 PSI / 111 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1760 lbs - 58/ 37.80/50.39 in | Shop Now 12099.99 USD | 17999.99 CAD |

40 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 186 CFM @ 100 PSI / 111 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1760 lbs - 58/ 37.80/50.39 in | Shop Now 12099.99 USD | 17999.99 CAD |

50 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 229 CFM @ 100 PSI / 168 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1496.00 lbs - 58.00/ 41.00/49.00 in | Shop Now 18699.99 USD | 20399.99 CAD |

50 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 229 CFM @ 100 PSI / 168 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1496.00 lbs - 58.00/ 41.00/49.00 in | Shop Now 15399.99 USD | 20099.99 CAD |

50 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 229 CFM @ 100 PSI / 168 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 1496.00 lbs - 58.00/ 41.00/49.00 in | Shop Now 15399.99 USD | 20399.99 CAD |

60 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 261 CFM @ 100 PSI / 204 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 3300 lbs - 58/ 37.80/50.39 in | Shop Now 20349.99 USD | 22799.99 CAD |

60 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 261 CFM @ 100 PSI / 204 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 3300 lbs - 58/ 37.80/50.39 in | Shop Now 19249.99 USD | 22799.99 CAD |

60 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 261 CFM @ 100 PSI / 204 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 3300 lbs - 58/ 37.80/50.39 in | Shop Now 18149.99 USD | 22799.99 CAD |

75 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 339 CFM @ 100 PSI / 239 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 4180 lbs - 58/ 37.80/50.39 in | Shop Now 25299.99 USD | 29999.99 CAD |

75 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 339 CFM @ 100 PSI / 239 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 4180 lbs - 58/ 37.80/50.39 in | Shop Now 25299.99 USD | 34999.99 CAD |

100 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 443 CFM @ 100 PSI / 325 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 5500 lbs - 58/ 37.80/50.39 in | Shop Now 30249.99 USD | 42999.99 CAD |

100 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 443 CFM @ 100 PSI / 325 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 5500 lbs - 58/ 37.80/50.39 in | Shop Now 30249.99 USD | 42999.99 CAD |

100 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 208-230V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 443 CFM @ 100 PSI / 325 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 5500 lbs - 58/ 37.80/50.39 in | Shop Now 39999.99 USD | 45999.99 CAD |

125 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 550 CFM @ 100 PSI / 407 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 6490 lbs - 75/ 49.21/62.60 in | Shop Now 36299.99 USD | 52999.99 CAD |

125 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 550 CFM @ 100 PSI / 407 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 6490 lbs - 75/ 49.21/62.60 in | Shop Now 36299.99 USD | 52999.99 CAD |

150 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 718 CFM @ 100 PSI / 518 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 7040 lbs - 90/ 61/76 in | Shop Now 47299.99 USD | 73599.98 CAD |

150 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 718 CFM @ 100 PSI / 518 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 7040 lbs - 90/ 61/76 in | Shop Now 47299.99 USD | 73599.98 CAD |

200 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 1020 CFM @ 100 PSI / 750 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 7920 lbs - 98/ 66.93/72.83 in | Shop Now 54999.99 USD | 81319.99 CAD |

200 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 1020 CFM @ 100 PSI / 750 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 7920 lbs - 98/ 66.93/72.83 in | Shop Now 54999.99 USD | 81319.99 CAD |

250 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 1400 CFM @ 100 PSI / 1100 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 8800 lbs - 98/ 67/73 in | Shop Now 65999.99 USD | 99600.00 CAD |

250 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 1400 CFM @ 100 PSI / 1100 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 8800 lbs - 98/ 67/73 in | Shop Now 65999.99 USD | 99600.00 CAD |

300 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 1357 CFM @ 100 PSI / 1018 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 10802 lbs - 146/ 144/89 in | Shop Now 87999.99 USD | 139199.99 CAD |

300 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 1357 CFM @ 100 PSI / 1018 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 10802 lbs - 146/ 144/89 in | Shop Now 87999.99 USD | 139199.99 CAD |

350 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 1540 CFM @ 100 PSI / 1200 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 9900 lbs - 74.80/ 110.00/76.77 in | Shop Now 99999.99 USD | 149199.99 CAD |

500 HP Variable Speed Drive Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 35% Energy Savings) Free Air Delivery 2250 CFM @ 100 PSI / 1800 CFM @ 175 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 12000 lbs - 89.00/ 140.00/97.00 in | Shop Now 149599.99 USD | 203319.99 CAD |