Understanding ISO 8573-1 Air Quality Standards

Compressed air systems power everything from manufacturing equipment to pneumatic tools across countless industrial operations. However, not all compressed air meets the same quality requirements. Understanding ISO 8573-1 air quality standards ensures compressed air meets specific purity levels for various applications.

This international standard establishes clear guidelines for measuring and categorizing contaminants in compressed air systems. Whether your facility requires air for food processing, pharmaceutical manufacturing, or general industrial use, understanding these standards ensures optimal performance and product quality. The classification system addresses three primary contaminant categories and provides detailed specifications for each purity class.

What ISO 8573-1 Standards Cover

ISO 8573-1 air quality standards encompass three distinct contamination categories that affect compressed air quality. These categories address solid particles, water content, and oil contamination, each with specific measurement criteria and classification levels.

Solid particle contamination includes dust, dirt, and other particulate matter that can damage sensitive equipment or compromise product quality. The standard defines particle size ranges and maximum allowable concentrations for each purity class. Water contamination addresses both liquid water and water vapor content, which can cause corrosion, freeze damage, and operational failures. Oil contamination covers lubricating oils from compressors as well as hydrocarbon vapors that may enter the system.

Each contamination category receives a numerical classification from 0 to 9, with lower numbers indicating higher purity levels. Class 0 represents the highest purity level with the strictest contamination limits, while higher numbers allow for increased contamination levels suitable for less critical applications.

Particle Classification Requirements

Solid particle contamination receives careful attention within the ISO 8573-1 framework due to its potential impact on equipment performance and product quality. The standard establishes particle size ranges and maximum concentration limits for each purity class.

Class 1 particle purity allows a maximum of 20,000 particles per cubic meter in the 0.1 to 0.5 micrometer size range, with additional limits for larger particles. Class 2 permits higher concentrations, making it suitable for general manufacturing applications where ultra-high purity is not essential. Classes 3 through 6 progressively allow higher particle concentrations for less demanding applications.

The measurement methodology requires specialized particle counting equipment capable of detecting particles across the size ranges. Regular testing ensures systems maintain their designated purity class and identify potential filtration system issues before they impact operations.

Water Content Standards

Water contamination poses significant challenges for compressed air systems, potentially causing equipment damage, product contamination, and operational inefficiencies. The ISO 8573-1 standard addresses both pressure dew point and liquid water content to provide comprehensive moisture control guidelines.

Class 1 water purity requires a pressure dew point of -70 degrees Celsius or lower, effectively eliminating virtually all water vapor from the compressed air stream. This stringent requirement suits pharmaceutical manufacturing, electronics production, and other applications where moisture cannot be tolerated. Class 2 allows a pressure dew point of -40 degrees Celsius, suitable for many food processing and precision manufacturing applications.

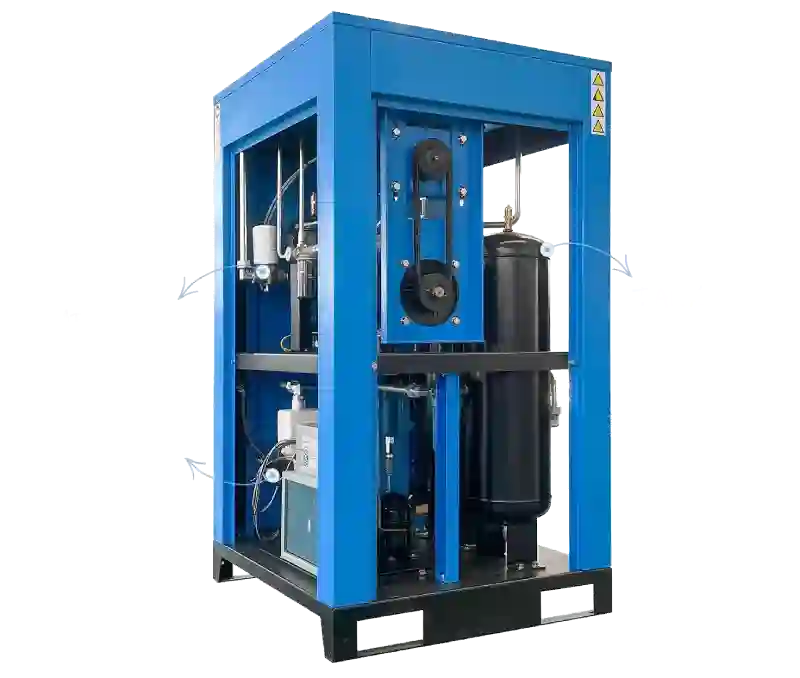

Higher classification numbers permit increased moisture levels, with Class 6 allowing pressure dew points up to +10 degrees Celsius for applications where moderate moisture content does not impact operations. An air compressor and dryer package typically includes refrigerated or desiccant dryers designed to achieve the required moisture levels for each application.

Oil Contamination Control

Oil contamination represents one of the most challenging aspects of compressed air purity, as traditional lubricated compressors introduce oil into the air stream through normal operation. The ISO 8573-1 standard establishes strict limits for total oil content, including both liquid oil and oil vapor.

Class 1 oil purity permits a maximum total oil content of 0.01 mg/m³, requiring oil-free compression technology or highly effective oil removal systems. This level suits food processing, pharmaceutical manufacturing, and other applications where oil contamination cannot be accepted. Class 2 allows up to 0.1 mg/m³ total oil content, suitable for many manufacturing processes with moderate contamination sensitivity.

Classes 3 and 4 permit higher oil concentrations for general industrial applications where oil presence does not significantly impact operations. However, even these classifications require effective filtration systems to maintain consistent air quality and protect downstream equipment from oil-related damage.

Testing and Verification Methods

Proper testing procedures ensure compressed air systems maintain their designated purity classifications throughout their operational life. The ISO 8573-1 standard specifies detailed testing methodologies for each contamination category, requiring specialized equipment and trained personnel.

Particle testing utilizes laser particle counters capable of detecting and sizing particles across the specified ranges. These instruments provide real-time particle concentration data, enabling immediate identification of filtration system issues or contamination sources. Testing frequency depends on application criticality and system design, with some applications requiring continuous monitoring.

Water content testing employs chilled mirror dew point analyzers or capacitive sensors to measure moisture levels accurately. Oil testing requires specialized collection methods and laboratory analysis to quantify total oil content, including both liquid oil and vapor phases. Regular testing schedules maintain system performance and ensure compliance with quality requirements.

Implementation Considerations

Successfully implementing ISO 8573-1 standards requires careful system design and component selection to achieve the required purity levels cost-effectively. Different applications demand varying purity classes, and over-specification can result in unnecessary costs and energy consumption.

System design must consider the interaction between different purification technologies and their cumulative effect on air quality. Filtration systems require proper sizing and sequencing to achieve target purity levels while maintaining adequate flow rates and pressure levels. Maintenance schedules must align with filter replacement intervals and testing requirements to ensure consistent performance.

Documentation and record-keeping support compliance verification and help identify system performance trends over time. Proper training ensures personnel understand testing procedures, maintenance requirements, and troubleshooting techniques necessary for maintaining air quality standards.

Making Informed Air Quality Decisions

The ISO 8573-1 standard provides a reliable framework for specifying and maintaining compressed air quality across diverse industrial applications. Understanding these classifications enables informed decisions about system design, component selection, and maintenance practices that optimize both performance and cost-effectiveness.

Proper implementation of these standards protects sensitive equipment, ensures product quality, and maintains operational reliability. Regular testing and maintenance according to ISO 8573-1 air quality standards prevents costly contamination issues and extends equipment life.

Working with qualified compressed air professionals ensures your system meets the appropriate purity classifications for your applications while maintaining optimal energy efficiency and operational costs.