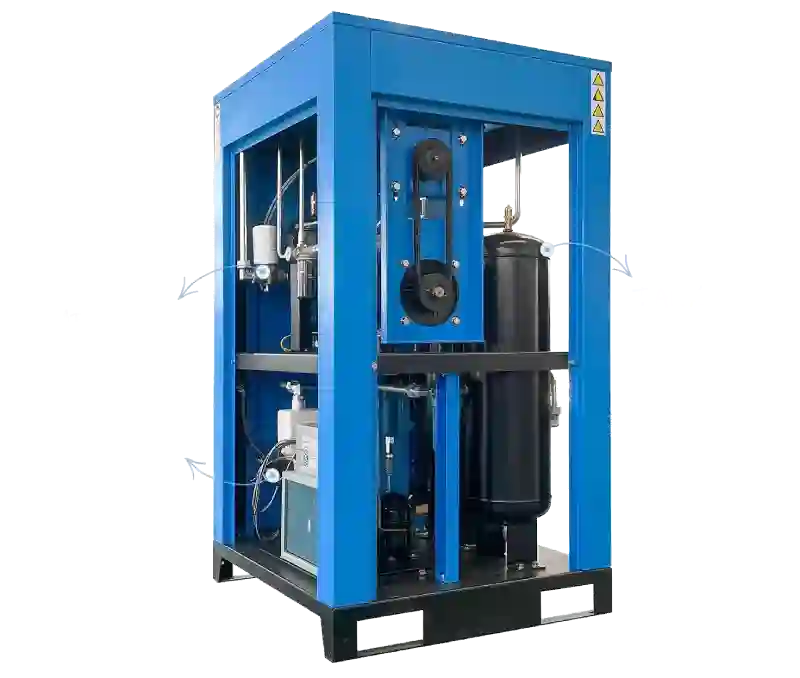

Two-Stage Air Compressor

Unmatched Efficiency with Two-Stage Compression

- 20% more Energy Saving than VSD

- 55% more saving than standard Compressor

The highest efficiency in the market

What is the Two Stage compression technology ?

First stage compression unit and the second stage compression unit are integrated in one air end driven directly by the helical gear, the optimal linear speed for each stage. This integration allows two-stage air compressors to optimize pressure distribution across stages. This, in turn, results in reduced energy wastage and enhanced output.

After the first stage compression, constant pressure compression by intensify spread oil cooling, reduce the second stage compression suction temperature, ensure that the second stage compression unit is close to isothermal compression. The process minimizes thermal stresses and maximizes the compressor’s efficiency to ensure consistent, high-quality air output.

Compression ratio reasonable distribution, optimized bearing design, second stage compression reduces the compression ratio of each stage, reduces internal leakage, improves the volume efficiency, reduces the bearing load, and improves the life of the air end.

What advantages does a Two Stage compressor have ?

- US Air’s two stage variable speed drive screw is at least 20% more efficient than any other variable speed single stage screw

- It can be up to 50% more efficient than your fixed speed screw compressor

- Using four rotors instead of two, this compressor will deliver more air using less electricity. The savings can be upwards of $50,000.00 annually

MORE EFFICIENT THAN ANY OTHER COMPRESSORS

60 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 299 CFM @ 100 PSI / 162 CFM @ 230 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 3630 lbs - 75/ 49.21/62.59 in | Shop Now 29999.99 USD | 0 CAD |

60 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 299 CFM @ 100 PSI / 162 CFM @ 230 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 3630 lbs - 75/ 49.21/62.59 in | Shop Now 19799.99 USD | 26909.99 CAD |

75 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 422 CFM @ 100 PSI / 225 CFM @ 230 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 4330 lbs - 82.67/ 49.21/66.14 in | Shop Now 36999.99 USD | 0 CAD |

75 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 422 CFM @ 100 PSI / 225 CFM @ 230 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 4330 lbs - 82.67/ 49.21/66.14 in | Shop Now 36999.99 USD | 0 CAD |

125 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 756 CFM @ 100 PSI / 525 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 6490 lbs - 82.67/ 49.21/66.14 in | Shop Now 47299.99 USD | 0 CAD |

150 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 930 CFM @ 100 PSI / 630 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 6800 lbs - 90/ 61/76 in | Shop Now 54999.99 USD | 0 CAD |

250 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 1400 CFM @ 100 PSI / 1100 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 8000 lbs - 103.10/ 80.70/85.80 in | Shop Now 87999.99 USD | 0 CAD |

250 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 1400 CFM @ 100 PSI / 1100 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 8000 lbs - 103.10/ 80.70/85.80 in | Shop Now 87999.99 USD | 0 CAD |

300 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 1650 CFM @ 100 PSI / 1100 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 10000 lbs - 114.00/ 72.93/81.14 in | Shop Now 109999.99 USD | 0 CAD |

350 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 1840 CFM @ 100 PSI / 1440 CFM @ 190 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 9900 lbs - 111/ 90/90 in | Shop Now 126499.99 USD | 0 CAD |

400 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 2050 CFM @ 100 PSI / 1600 CFM @ 150 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 10900 lbs - 140/ 88.40/96.77 in | Shop Now 149599.99 USD | 0 CAD |

450 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 2330 CFM @ 100 PSI / 1800 CFM @ 150 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 11000 lbs - 140/ 88.40/96.77 in | Shop Now 175999.99 USD | 0 CAD |

450 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 2330 CFM @ 100 PSI / 1800 CFM @ 150 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 11000 lbs - 140/ 88.40/96.77 in | Shop Now 175999.99 USD | 0 CAD |

500 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 2490 CFM @ 100 PSI / 1990 CFM @ 150 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 12000 lbs - 140/ 88.40/96.77 in | Shop Now 219999.99 USD | 0 CAD |

500 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 575-600V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 2490 CFM @ 100 PSI / 1990 CFM @ 150 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 12000 lbs - 140/ 88.40/96.77 in | Shop Now 219999.99 USD | 0 CAD |

700 HP Two Stage VSD Rotary Screw Air Compressor Voltage: 460-480V 3Phase VSD Compressor (Upto 50% Energy Savings) Free Air Delivery 3550 CFM @ 100 PSI / 3550 CFM @ 120 PSI 10 Year Bumper to Bumper Exchange Warranty Dimensions: 16000 lbs - 130.00/ 210.00/122.00 in | Shop Now 285999.99 USD | 0 CAD |