Top Air Compressor Accessories You Need in 2025

Air compressors are a critical component in various industries, from automotive to manufacturing. However, maximizing the efficiency, performance, and utility of your compressor requires more than just the component itself. You must also have accessories.

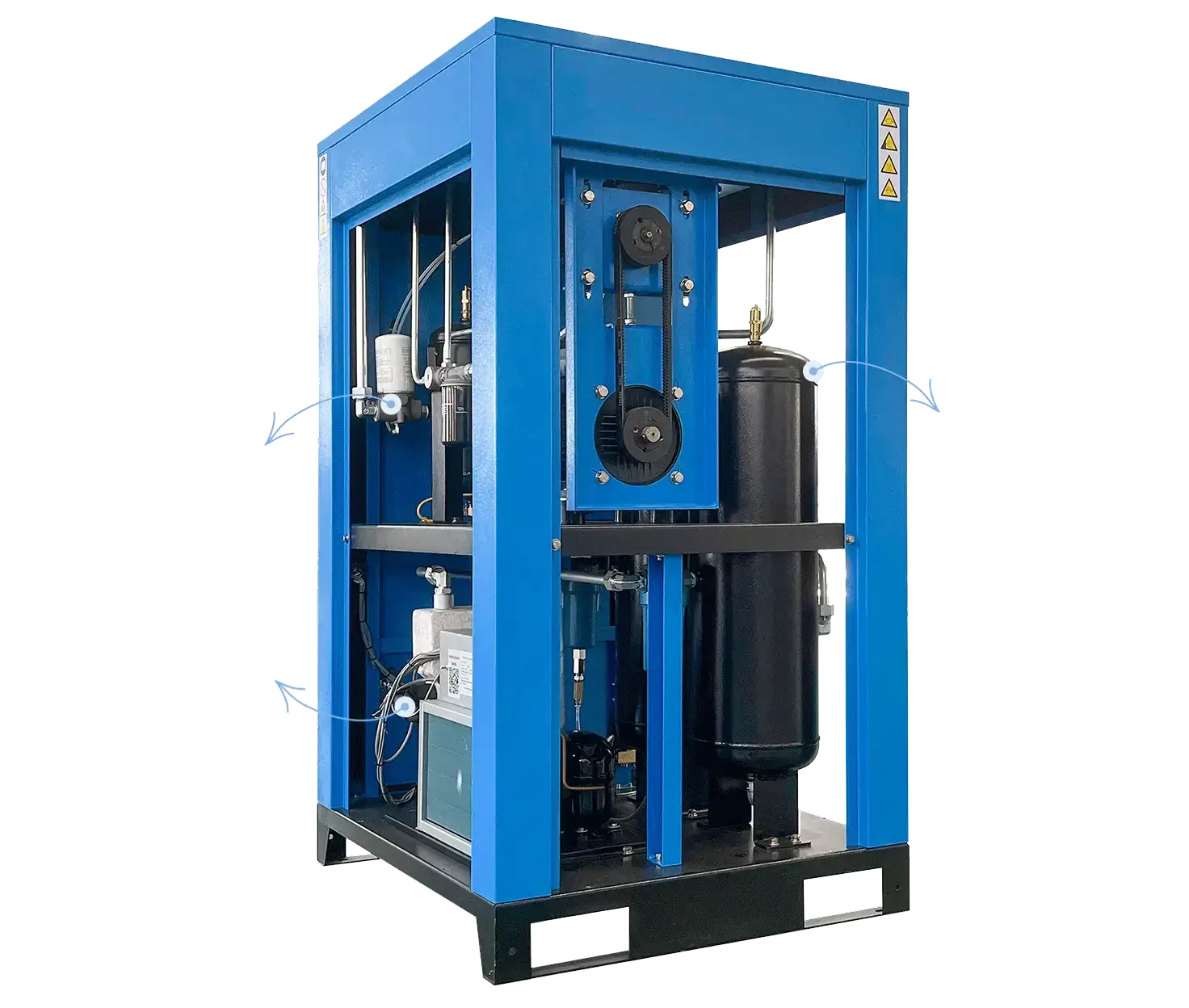

This guide will unveil the top air compressor accessories you need in 2025 so your system operates at its full potential. Whether you operate a compact unit or a high-performance three-phase rotary screw air compressor, we’ve compiled options that integrate seamlessly into your workflow, setting you up for success in the coming year.

Air Filters for Improved Air Quality

A high-performance air filter is a must for removing contaminants that can harm your equipment and compromise air quality. Filters can catch dust, dirt, oil particulates, and moisture, all of which can build up over time within your compressor system and connected tools. A reliable air filter extends the life of your machinery and enhances overall system performance.

Today, advanced air filters equipped with auto-drain mechanisms offer enhanced convenience over standard filters. These advanced filters have features that eliminate the need for manual drainage, simplifying maintenance while promoting consistent filtration.

Pressure Regulators for Accurate Control

Accurate pressure delivery is essential for safety and efficiency when using an air compressor. A pressure regulator allows you to fine-tune the output pressure of your air compressor to match the needs of specific tools or equipment. Without proper control, excess pressure can lead to overexertion, tool damage, and energy wastage.

Modern pressure regulators integrate precise calibration gauges that maintain stability, delivering optimal results. These pressure regulators are especially relevant for industries that rely on precision tools, as consistent air pressure is nonnegotiable. When outfitting your air compressor with a pressure regulator, choose a durable, adjustable model. You’ll reduce energy costs while improving operational safety.

Air Hoses for Maximum Reach and Longevity

High-quality air hoses provide reliable airflow so tools can function smoothly. Hose technologies have continued to advance in the 2020s, with the tech in 2025 emphasizing flexibility, durability, and extended reach to simplify operations.

Rubber and hybrid polymer hoses have gained popularity due to their exceptional durability and wear resistance. These hoses stay pliable in extreme temperatures for reliable functionality in various environments, including construction sites and industrial warehouses. Look for air hoses reinforced with braided wire or synthetic fibers for long-term usability. These features make the hoses suitable for high-pressure systems.

Lubricators for Optimal Efficiency

An in-line lubricator is a game changer for compressed air systems that rely on lubricated tools. This accessory ensures that the mechanisms within your tools receive an accurate amount of oil to prevent wear and overheating.

Modern lubricators come with automated dispensing systems for the precision and convenience needed to extend the life of your tools. These systems also minimize the mess and guesswork often associated with manual lubrication. For air compressors used in busy environments, such as manufacturing plants, lubricators provide an additional layer of protection for uninterrupted performance.

Oil-Water Separators for Cleaner Operation

Maintaining the integrity of air compressor performance also involves addressing by-products such as oil and water. An oil-water separator captures oil particles produced during compression so they don’t contaminate the air supply or harm the environment.

Efforts to simplify oil-water separation have led to the development of accessories that are as efficient as they are easy to maintain. With filters capable of separating smaller particles, these systems maintain the highest level of air quality. Using an oil-water separator can help you avoid fines from improperly discarded waste while preserving the lifespan of your compressor system.

Couplers and Fittings for Seamless Connectivity

Reliable couplers and fittings can maintain seal airtightness and deliver uninterrupted airflow. As 2025 continues, advancements in quick-connect coupler technology now allow you to switch between tools with minimal effort, speeding up workflows. Further, durable materials like stainless steel and brass prevent corrosion for longevity in demanding conditions. High-quality fittings minimize leaks, optimize energy consumption, and help you maximize the value of your compressed air system.

Tank Drains for Preventing Moisture Buildup

Moisture is an inevitable by-product of compressed air generation, forming as a result of the cooling process during compression. If left uncontrolled, this moisture can lead to rust, corrosion, and reduced system efficiency, potentially damaging your air compressor and connected tools over time. Tank drains are essential for removing excess moisture so your compressor operates smoothly and lasts longer.

Auto-drain systems, a major trend in 2025, offer an advanced solution by automating the moisture removal process and eliminating the need for manual intervention. These systems are especially beneficial for high-capacity compressors or facilities with heavy usage, as they save operators time and effort while improving overall system reliability. By investing in a robust tank drain, you protect your equipment and the quality of your operations.

Storage Solutions for Better Organization

Proper air compressor accessory storage is a crucial yet often-overlooked aspect of workshop efficiency. A reliable storage system maintains component condition, prevents damage or wear from improper handling, and keeps parts easily accessible.

Purpose-built storage solutions, such as wall-mounted racks, durable cabinets, and portable compartments, make it easy to organize everything from hoses to filters, couplers, fittings, and adapters. This level of organization is particularly important in fast-paced or high-demand environments, where misplaced parts can lead to costly delays.

Modular storage systems that integrate seamlessly into existing setups are ideal for busy workshops, offering flexibility to expand as your needs grow. By creating a well-structured storage system, you improve productivity, reduce downtime, and maintain the condition of your tools so they’re always accessible when you need them most.

Power Your Workflow With the Right Accessories

Optimizing your air compressor with tailored accessories unlocks its full potential. From maintaining consistent air quality to improving operational efficiency, these tools enhance everyday performance and extend the lifespan of your investment.

The top air compressor accessories you need in 2025 are just as essential as the compressor itself. The right combination of tools and accessories will make a noticeable difference in how smoothly your operations run. Prepare for 2025 with confidence by upgrading your compressor system today.