The Ultimate Guide to Rotary Screw Air Compressors

Air compressors are found across industries worldwide. From manufacturing to health care, air compressors keep businesses running efficiently. Among the various types of compressors, rotary screw air compressors stand out as a top choice, but what makes them such a good investment?

This is the ultimate guide to rotary screw air compressors. We’ll cover everything you need to know to take advantage of their benefits. Whether you’re a seasoned industry professional or shopping for your first air compressor, you’ll get the most out of your new tool with this information.

What Are Rotary Screw Air Compressors?

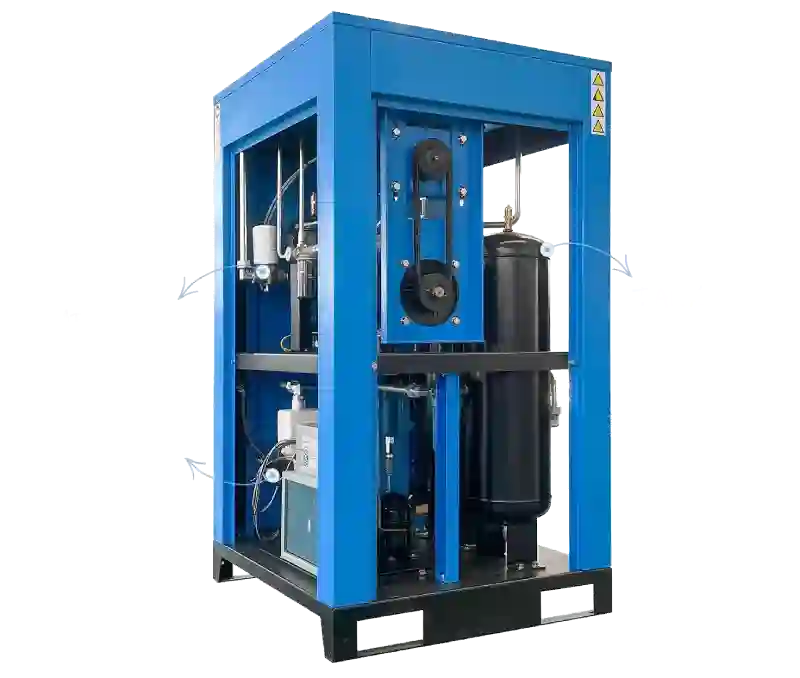

Rotary screw air compressors are a type of gas compressor that uses two interlocking screws, or rotors, to compress air. Unlike piston-driven reciprocating compressors, rotary screw compressors offer a continuous supply of compressed air, making them ideal for operations requiring steady and reliable air pressure.

These compressors are highly valued for their efficiency, low noise, and durability, making them suitable even for the most demanding tasks.

How Do Rotary Screw Compressors Work?

First, ambient air enters the compressor through the intake valve. Then, inside the machine, the two rotor screws turn in opposite directions, trapping air between the rotor gaps. As the rotors spin, the trapped air is compressed as it moves toward a smaller space at the outlet.

In some cases, an oil injection system cools the compressed air and lubricates the rotors. The oil is later separated from the air for reuse. The result? Clean, pressurized air is ready for any application.

Industries That Benefit From Rotary Screw Air Compressors

Rotary screw compressors are vital to several industries. Below are some of those industries and how they use compressors.

- manufacturing: continuous air supply for assembly lines, CNC machines, and pneumatic tools

- automotive: painting, tire inflation, and operating robotics

- food and beverage: ensuring air purity for packaging processes and food safety

- pharmaceuticals: for hygiene and precise mixing in drug formulations

- health care: supporting respirators, dental tools, and sterilization processes

- construction: powering pneumatic tools, sandblasting equipment, and concrete mixers

With so many use cases, it’s no wonder these tools are such a common sight in the manufacturing world.

Advantages of Rotary Screw Compressors Over Reciprocating Compressors

Many businesses choose rotary screw compressors over the more traditional reciprocating model. This is because, unlike reciprocating compressors that work in cycles, rotary screw compressors provide an uninterrupted flow of compressed air, guaranteeing continuous operation.They also consume less power than piston-based systems for similar air output, and they operate more quietly.

On top of that, they’re durable. They have fewer moving parts, resulting in longer operational lifespans with minimal wear and tear.They also require less upkeep than reciprocating compressors. With so many advantages, it’s easy to see why rotary screw compressors often come out on top.

Types and Variations of Rotary Screw Compressors

Rotary screw compressors are not one-size-fits-all. Variants are designed to address specific requirements and use cases.

Oil-Injected Rotary Screw Compressors

These compressors use oil for lubrication, sealing, and cooling during the compression process. They are highly efficient and commonly used in industrial applications where air purity is not a critical factor.

Oil-Free Rotary Screw Compressors

Designed to provide 100 percent oil-free air, oil-free rotary screw compressors are ideal for industries requiring clean air, such as food and beverage, pharmaceuticals, and electronics manufacturing. They ensure no risk of contamination in sensitive processes.

Fixed-Speed Compressors

Fixed-speed compressors operate at a constant speed, making them well-suited for applications with a consistent air demand.

Variable-Speed Compressors

Variable-speed compressors adjust their motor speed to align with fluctuating air demand, leading to greater energy efficiency and cost savings in dynamic environments.

Key Features To Look for When Choosing a Rotary Screw Compressor

When selecting a rotary screw air compressor for your needs, here are the features to prioritize:

- Airflow capacity: Make sure the machine can meet your specific air demand, measured in cubic feet per minute (CFM).

- Pressure rating: Determine the pounds per square inch (PSI) requirement of your application to avoid underpowered or overpowered compressors.

- Energy efficiency: Look for models with energy-efficient motors, VSD technology, or certifications like ENERGY STAR ratings.

- Noise levels: Consider soundproof models or enclosures if your facility values a quieter work environment.

- Maintenance accessibility: Ensure that the compressor offers easy access for maintenance tasks like oil changes or filter replacements.

No matter what type of compressor you choose, it’s important to take the proper care steps from the start.

Proper Maintenance and Care for Rotary Screw Compressors

A well-maintained rotary screw compressor ensures long life and optimal performance. Stick to this checklist for appropriate maintenance procedures.

Regular Inspection

Conduct routine inspections to identify potential issues such as leaks, unusual noises, or worn-out parts. Addressing these problems early can prevent costly repairs and downtime.

Oil and Filter Changes

Follow the manufacturer’s recommendations for oil and filter changes. Clean filters and fresh oil ensure optimal performance and longevity of the compressor.

Drain Condensate Regularly

Moisture accumulates in the compressor over time, which can lead to corrosion and decreased efficiency. Regularly draining condensate is essential to maintain peak functionality.

Check and Tighten Connections

Periodically check all hoses, fittings, and connections to ensure there are no air leaks. Tighten any loose components to maintain efficiency and safety.

Monitor Operating Temperature

Keep an eye on the operating temperature to avoid overheating, which can lead to serious damage. Ensure proper ventilation to help manage heat dispersion.

Schedule Professional Servicing

While regular maintenance can be performed in-house, scheduling periodic professional servicing ensures that your compressor is running at peak efficiency and adheres to safety standards.

The Future of Rotary Screw Air Compressors

Advancements in technology indicate that the rotary screw compressor will continue evolving. Energy-efficient designs, smart integrations (think IoT monitoring for preventative maintenance), and customizable configurations are on the horizon. Businesses that adopt these innovations early will stand to gain significant advantages in efficiency and cost savings.

An Indispensable Tool Across Industries

Rotary screw air compressors have firmly established themselves as indispensable tools across various industries, owing to their reliability, efficiency, and adaptability. With advancements in technology pushing the boundaries of performance, these tools are set to provide even greater value in the years to come. Equipped with the ultimate guide to rotary screw air compressors, you can stay ahead in a competitive market.

For businesses, choosing the right compressor is an investment in a more sustainable and productive future. If you’re looking to modernize your operations and invest in top-tier efficiency, US Air Compressor has you covered. With us as a partner, you can shop for air compressors knowing you’re getting something that you can depend on!