Should You Repair or Replace Your Air Compressor?

Air compressors are pivotal for powering tools, machinery, and production lines in various industries. However, when your unit starts to falter, it can stall your operations and leave you stuck with an important decision: should you repair or replace your air compressor entirely?

The right decision can save you money, downtime, and hassle, especially if you rely on your air compressor for crucial tasks. Read on for the key factors to consider when making this decision so you can avoid costly missteps along the way.

Why Making the Right Choice Matters

An air compressor is a major investment, and keeping it in optimal condition helps your business run smoothly. Frequent breakdowns and poor efficiency can derail deadlines, frustrate your team, and harm productivity. On the other hand, replacing a compressor too early could mean unnecessary expenses. Striking the right balance is key to getting the most out of your equipment.

Signs Your Air Compressor Can Be Repaired

The first step in deciding whether to repair or replace your air compressor is to assess its condition. Not all malfunctions warrant an expensive replacement. Here are key signs that a repair may be the right choice:

The Issue Is Minor

If the problem is as simple as a leaking hose, faulty pressure switch, or worn seals, repairs are typically quick and cost-effective. These minor issues can often be resolved with minimal downtime and at a fraction of the replacement cost.

The Compressor Is Fairly New

Air compressors are built to last. High-quality models can operate effectively for 15 to 20 years with proper maintenance, depending on usage. If your compressor is relatively new (within five to seven years old), repairing makes more financial sense unless the repair costs are exorbitant.

The Repair Costs Are Less Than 50 Percent of Replacement Costs

A general rule of thumb is that repairs costing less than 50 percent of the price of a new compressor are almost always worthwhile. Anything above that warrants closer consideration, especially if your current system is nearing the end of its life cycle.

Availability of Replacement Parts

If replacement components for your specific model are readily available, repairs can often be done quickly. However, if parts are outdated or hard to find, repairs may lead to extended downtime, making a replacement more appealing.

The Compressor Still Meets Your Needs

Sometimes, businesses outgrow their air compressors if production demands increase enough. If your compressor still meets your operational requirements, repairing it could keep things running smoothly without shelling out for an upgrade.

Signs It’s Time To Replace Your Air Compressor

While repairing is usually a cost-effective and eco-friendly option, there are circumstances where replacing the air compressor is the wisest choice. If you notice the following indicators, it may be time to invest in a new system:

Persistent Downtime

If your compressor is constantly breaking down despite past repairs, it can disrupt workflow and cost you more money in the long run. Frequent downtime is a telltale sign that the system’s reliability is inadequate.

Skyrocketing Energy Consumption

Older compressors are less efficient, so rising utility bills can add up over time. If you notice inflated energy costs, upgrading to a modern, energy-efficient model could save you money in operational expenses.

Outdated Technology

Technology evolves rapidly, and air compressor models from a decade ago often lack modern features, such as variable speed drives or intelligent controls. These upgrades improve efficiency and precision, making the investment in a new unit worthwhile.

Repairs Are Too Costly

If repair quotes exceed half the cost of a replacement or require rare, expensive parts, it’s a sign that a long-term fix isn’t feasible. Spending heavily on repairs for an older unit is often akin to throwing money down a black hole.

Your Air Requirements Have Changed

If your business operations have scaled up and your air requirements have grown beyond your existing compressor’s capacity, upgrading to a larger or more capable unit could prevent future problems and better align with your needs.

How To Choose Between Repairing and Replacing

After learning the signs for air compressor repair and replacement, consider these practical steps to make the best decision:

- Conduct a cost-benefit analysis: Evaluate the total cost of repairs and the price of a new compressor in detail. Compare these costs to the benefits of reliability, efficiency, and potential savings over time.

- Consult a professional technician: Having a qualified technician assess your compressor can provide clarity on whether repairs will extend its lifespan or if replacement is the smarter move. The technician can also provide approximate timelines for both options.

- Factor in downtime: Even minor repairs can result in downtime, which directly affects your productivity. Calculate the potential costs of lost production when making your decision.

- Look for incentives or financing options: Many dealers and manufacturers offer trade-in programs or incentives for upgrading your equipment. Financing options can also reduce the upfront cost of purchasing a new compressor, making replacement more feasible.

- Plan for the future: Consider your business goals and projections. Will your current compressor meet your needs in the long run, or will it eventually require replacement anyway? Factor in potential growth and expansion when deciding.

Whether you choose to repair or replace your air compressor, you must stay vigilant so additional problems don’t arise during operation.

Maintaining Your Air Compressor To Extend Its Lifespan

Regular maintenance is essential for maximizing the life and performance of your equipment. Here are some tips:

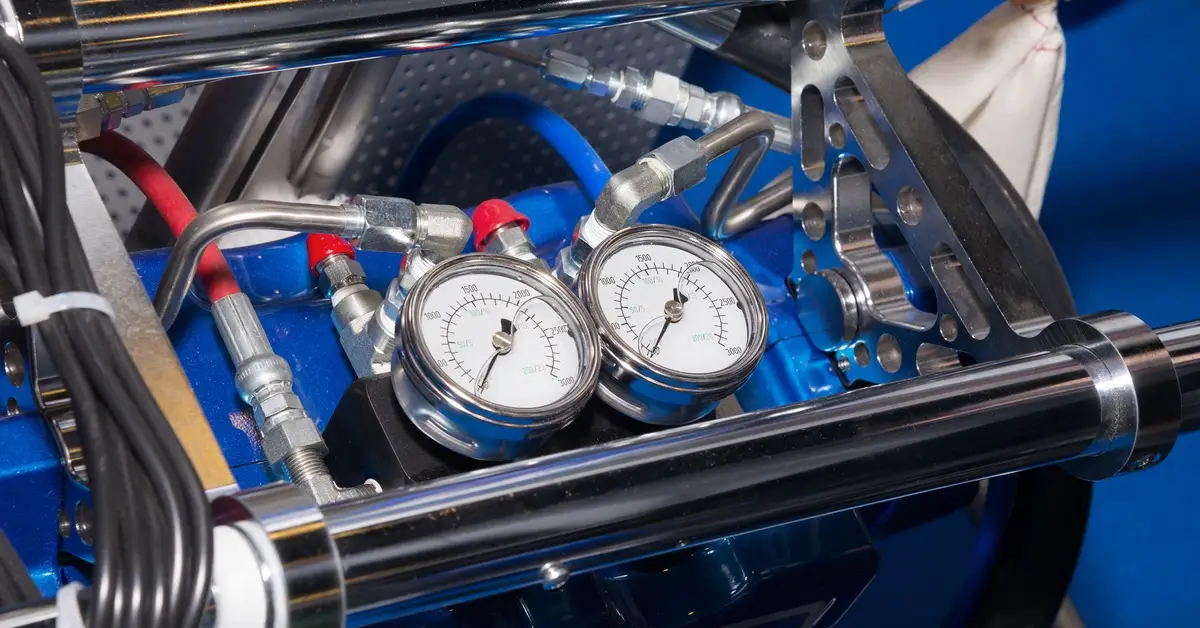

- Perform routine inspections: Check for leaks, wear, and pressure issues regularly.

- Stay on top of filter changes: Dirty filters reduce efficiency and strain the system.

- Schedule preventative maintenance: Work with a technician to develop a maintenance plan tailored to your compressor’s usage.

- Keep your workspace clean: Debris and contaminants can interfere with your system’s functionality.

- Monitor performance: Keeping an eye on energy consumption and runtime can alert you to potential issues before they escalate.

By taking the time and effort, you’ll have reliable air compressor systems for all your needs.

Make the Right Call for Your Compressor

Deciding whether you should repair or replace your air compressor system doesn’t have to be overwhelming. By understanding the extent of the issue, assessing repair costs versus replacement expenses, and consulting with professionals, you can make a choice that saves money and minimizes downtime. Knowing how to invest your money wisely is the best way to minimize operational costs.

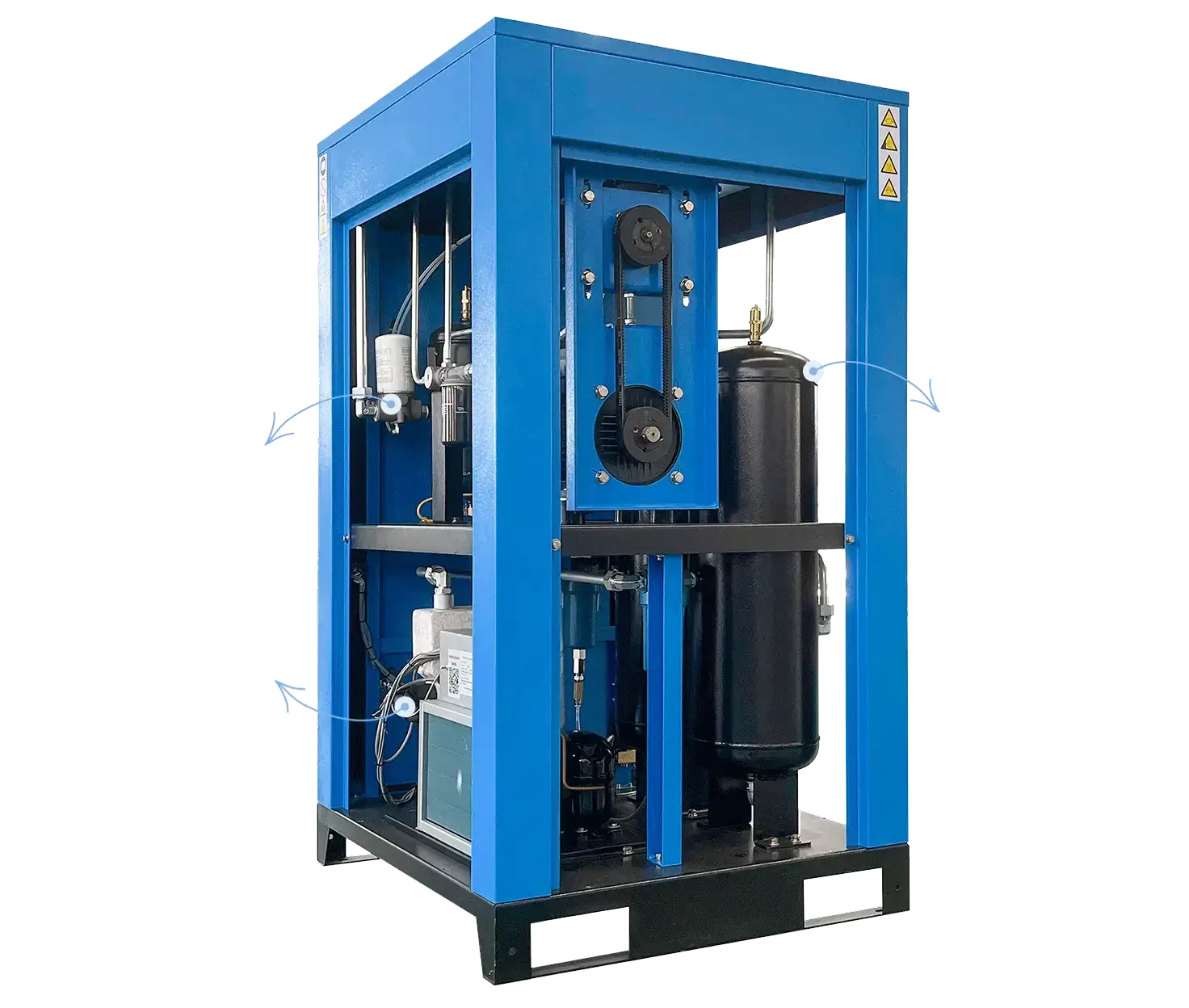

Are you ready to upgrade your air compressor system? At US Air Compressor, you can find a unit that fits your specific needs and budget. Our all-in-one air compressors are convenient and easy to use, taking the frustration out of your projects. Contact our team today to schedule an air compressor assessment and get your system running smoothly.