Revolutionize Your Air Compression with Oil-Free Scroll Technology

What is an Oil-Free Scroll Air Compressor?

An oil-free scroll compressor is a type of air compressor that uses two spiral-shaped scroll elements to compress air without the need for oil lubrication. Here are the key features and benefits of oil-free scroll compressors:

Operating Principle

- Uses two scroll elements: one fixed and one orbiting

- The orbiting scroll moves in a circular motion within the fixed scroll

- Air is trapped between the scrolls and compressed as it moves towards the center

- Delivers 100% oil-free air, certified to ISO 8573-1 Class 0 standards

Advantages

- Clean, contamination-free air: Eliminates risk of oil contamination

- Low maintenance: No oil changes or filter replacements required

- Energy efficient: Produces only the required amount of air

- Compact design: Small footprint ideal for limited spaces

- Quiet operation: Noise levels as low as 48 dBA

- Reliable performance: Fewer moving parts increase reliabilityOil-free scroll compressors are particularly well-suited for applications requiring pure, contaminant-free air, such as medical facilities, laboratories, food and beverage production, and electronics manufacturing

Key Characteristics

- Oil-free design: No oil used in the compression chamber

- Self-lubricating materials: Uses materials like Teflon instead of oil

- Fewer moving parts: Only two main components (fixed and orbiting scrolls)

- Continuous airflow: Provides a steady stream of compressed air

- Low noise and vibration: Quieter operation compared to other compressor types

Applications and Industries

Oil-free scroll compressors are ideal for:

- Medical and laboratory environments

- Pharmaceutical production

- Food and beverage manufacturing

- Electronics manufacturing

- Automotive painting

- R&D facilities

- Dental applications

Why Choose an Oil-Free Scroll Compressor?

An oil-free scroll compressor is a type of air compressor that uses two spiral-shaped scroll elements to compress air without the need for oil lubrication. Here are the key features and benefits of oil-free scroll compressors:

1. Clean, Contamination-Free Air

- Eliminates risk of oil contamination in sensitive processes

- Ensures product quality and safety

2. Ultra-Quiet Operation

- Noise levels as low as 48 dBA

- Suitable for noise-sensitive environments

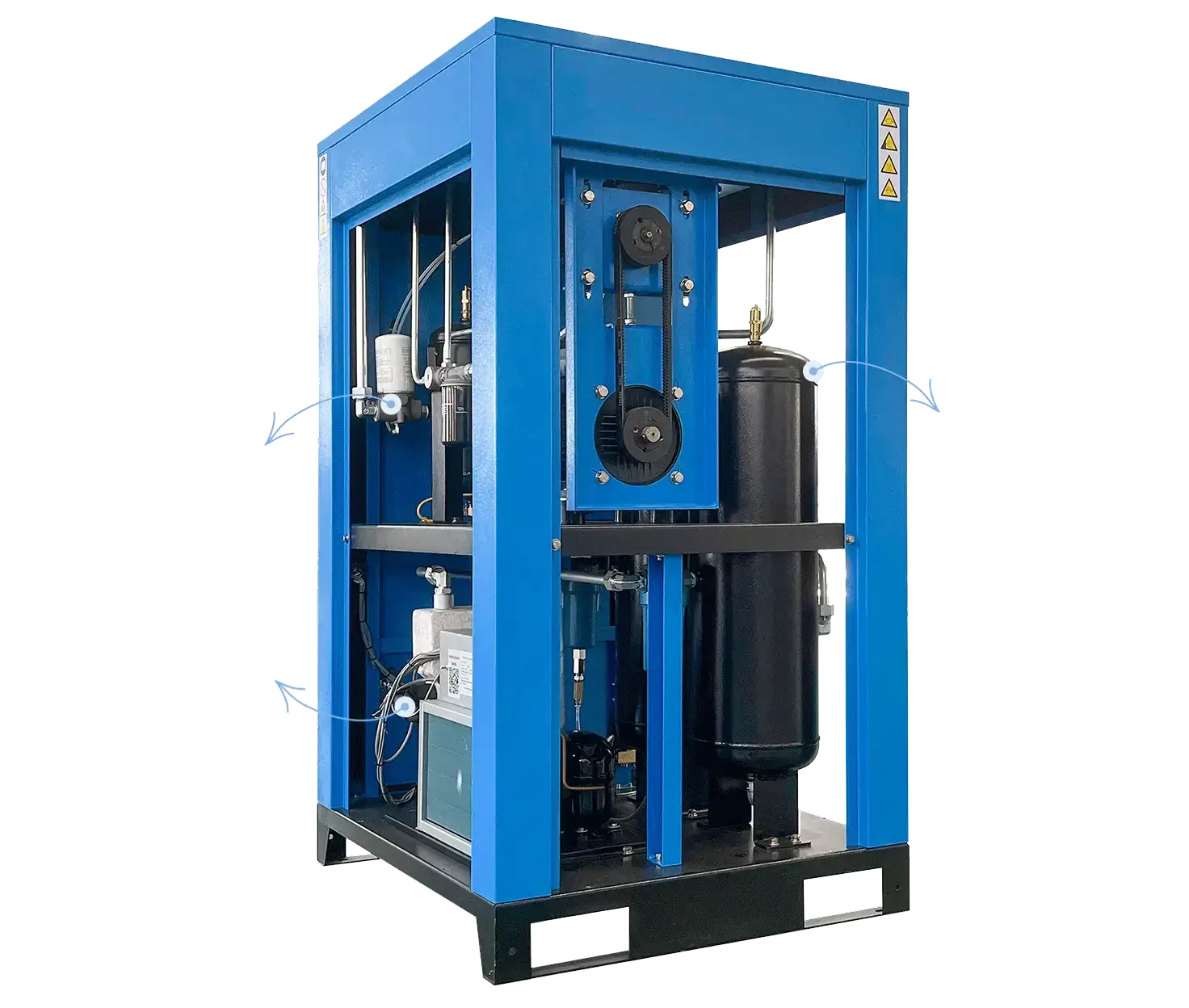

3. Compact and Space-Efficient

- Small footprint ideal for limited spaces

- Can be installed at point-of-use, reducing installation costs

4. Low Maintenance

- Fewer moving parts for increased reliability

- No oil changes or filter replacements required

5. Energy Efficient

- Produces only the required amount of air

- Potential for long-term cost savings

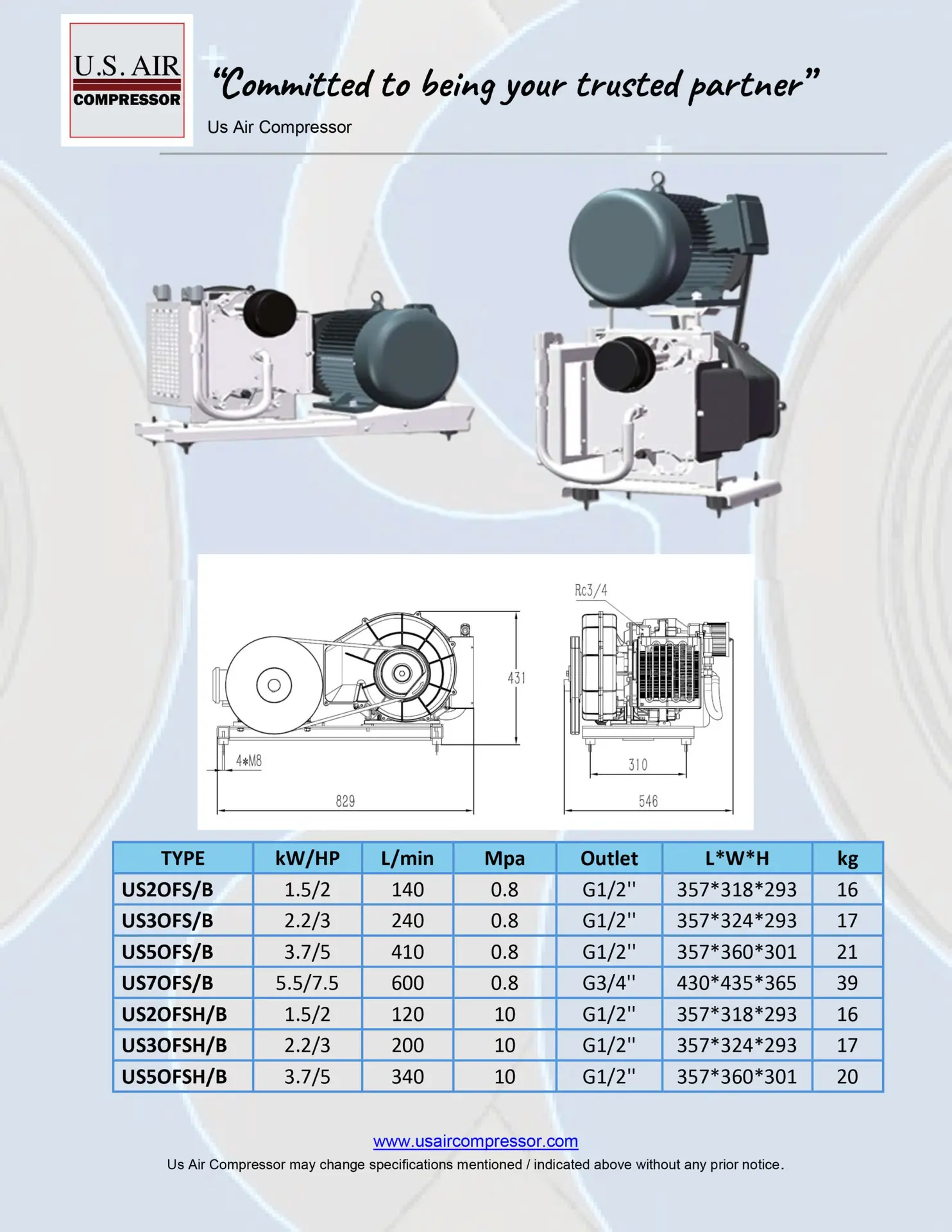

Direct Drive:

A Direct Drive Scroll Compressor is a type of air compressor that combines the scroll compression technology with a direct drive mechanism. Here are the key features and characteristics of a Direct Drive Scroll Compressor:

- More compact and lightweight

- Fewer moving parts, potentially lower maintenance

- Generally more energy-efficient

- Ideal for portable or space-constrained applications

Belt Drive:

A Belt Drive Scroll Compressor is a type of air compressor that utilizes a belt-driven mechanism to connect the motor to the scroll compression unit. This design allows for efficient operation and flexibility in performance. Here are the key features and characteristics of a Belt Drive Scroll Compressor:

- Can handle higher loads and pressures

- Potentially more powerful for heavy-duty applications

- May require more frequent maintenance (belt replacements)

- Slightly larger and heavier than direct drive models

Ready to Explore the World of Air Power ?

Trust us—you’re in good hands with a company that’s all about making smart and efficient compressors that work as hard as you do, and backed with a solid 10-year warranty