Get in touch

Frequently asked questions

Which compressor size do I need ?

The size of the compressor is a key factor to consider. It’s essential to evaluate your specific air requirements when making this decision. Selecting a compressor that is too small can lead to production issues during periods of high demand, while choosing one that is too large may result in energy inefficiency and increased ownership costs.

Additionally, understanding your flow and pressure requirements is critical. You need a compressor that provides adequate pressure to meet the demands of your application. Consider the amount of compressed air flow (CFM) required at a specific pressure (PSI) to ensure smooth operation. These factors will ultimately determine the appropriate compressor size for your needs.

What type of compressor do I need ?

There are various types of compressor technologies available, from rotary screw compressors to reciprocating piston compressors. When selecting the right technology, it is important to carefully consider your specific needs.

Factors such as the number of operating hours per year, whether your application requires a continuous or intermittent air supply, and potential fluctuations in demand should all be taken into account. Each compressor type offers unique features and benefits, and these variables will guide your decision in choosing the most suitable design for your requirements.

Which equipments do I need ?

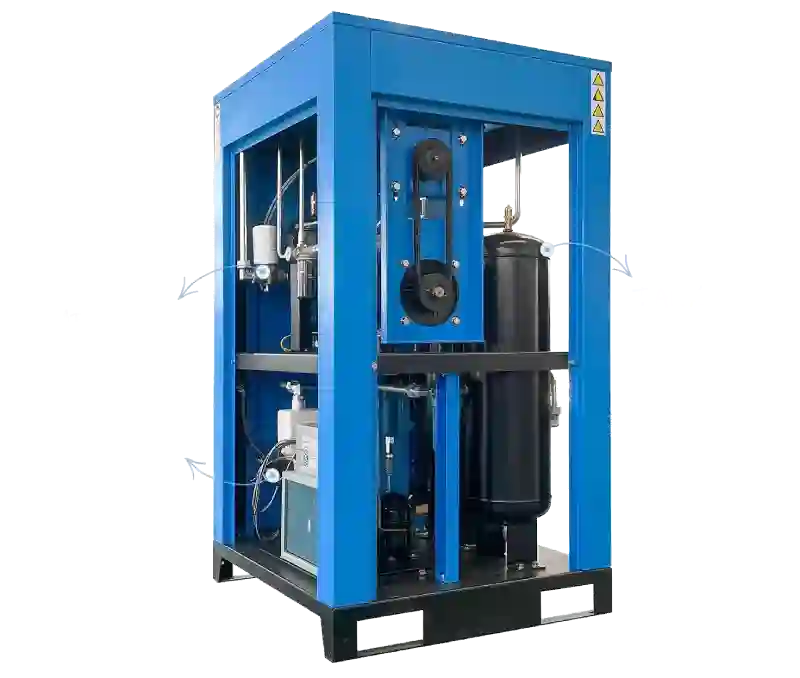

Creating a high-performance compressed air system requires more than just an efficient compressor. Downstream equipment and accessories play a critical role in optimizing and enhancing your overall operation.

A wide range of air treatment accessories, such as dryers, filters, and tanks, are available to support your system. These add-ons are essential for completing your setup and improving the efficiency and reliability of your installation.

I have different questions !

If you’re unsure, consider having an air audit conducted by a specialist. This can help you assess your air output requirements and provide valuable recommendations for improving the overall efficiency of your operation.

Our experts are available to guide you in selecting the optimal solution for your plant’s needs. We will evaluate factors such as air demand, air quality, pressure, flow rates, and any other relevant elements to provide you with tailored, professional advice.