Compressed Air 101: Everything You Should Know

Compressed air is essential for powering a wide variety of industries, yet its importance often goes unnoticed. From inflating tires to enabling large-scale industrial operations, compressed air is deeply embedded in our modern lives.

This blog will tackle compressed air 101, covering everything you should know to take advantage of its wide-ranging applications. Whether you’re curious about the workings of a compressor or looking for industry best practices, this guide will cover it all.

The Journey of Compressed Air

Compressed air has a history dating back centuries. Early blacksmiths used hand-operated bellows to create bursts of air that increased the temperature of their forges. However, its industrial relevance soared during the 19th century when compressed air was used to power mining tools and operate large-scale machinery.

Fast forward to today, compressed air systems are critical across numerous industries, such as manufacturing, healthcare, food processing, and construction. Despite its versatility, however, it’s also worth noting that compressed air systems consume significant energy, raising questions about their environmental footprint. With innovation on the rise, however, more sustainable approaches to harnessing compressed air are emerging.

The Science Behind Compressed Air

The concept of compressed air boils down to a few fundamental principles of physics.

Boyle’s Law

Boyle’s Law holds that, within a gas that has a constant temperature, the pressure and volume are inversely proportional. When you compress air in a confined space, its volume decreases while its pressure increases.

Charles’s Law

This law explains that when the pressure is constant, the volume of a gas increases with temperature. Understanding this principle is vital when working with compressed air, especially when heat is introduced during compression.

The Ideal Gas Law

A combination of Boyle’s and Charles’s laws, the ideal gas law captures how pressure, volume, and temperature interact in a gas. Though not directly tied to day-to-day operations, it remains the theoretical foundation behind how compressed air works.

These principles form the backbone of compressed air technology, ensuring its functionality across a diverse range of applications.

How Compressed Air Systems Work

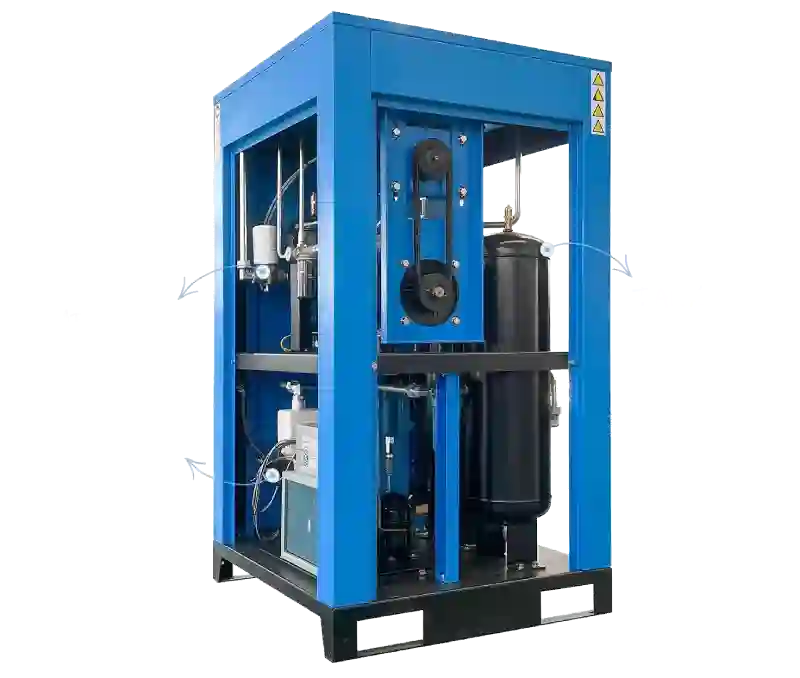

A compressed air system might seem complex at first, but it consists of a few key components working in harmony. Here’s a breakdown of its core elements:

1. The Compressor

At the heart of the system lies the compressor. It increases the pressure of air by reducing its volume. There are various types of compressors, including reciprocating, rotary screw, and centrifugal, each suited to different use cases.

2. Air Storage

Once compressed, the air is stored in a reservoir or a receiver tank. This ensures there’s a steady supply of air at your disposal when it’s needed.

3. Air Treatment

Compressed air isn’t inherently clean. It can pick up moisture, dust, and oil during the process. Treatment equipment like dryers and filters ensures that the air is clean and dry, which is critical for industries like healthcare and food manufacturing.

4. Distribution System

Finally, the compressed air moves through a network of pipes and hoses to reach its destination. Proper installation and maintenance of the system are essential to avoid leaks and pressure drops.

Common Uses of Compressed Air

Compressed air can be found in prominent applications across industries:

- Manufacturing: Compressed air powers tools on production lines, such as drills, grinders, and spray painters, making it the backbone of industrial manufacturing.

- Healthcare: Hospitals rely on compressed air for oxygen delivery systems, sterilization equipment, and even patient ventilation.

- Food processing: Compressed air is used to clean machinery, fill beverages, and power pneumatic systems that process and package food.

- Construction: From jackhammers to nail guns, compressed air powers many construction tools with consistent force and reliability.

- Automotive: Inflating tires, cleaning machinery, and even assisting in vehicle assembly are common automotive applications of compressed air.

This is just the tip of the iceberg. Nearly every industry has found ways to integrate compressed air into its operations.

Best Practices for Efficient and Safe Use

Compressed air systems can be resource-intensive, consuming a large chunk of a facility’s electricity. Proper maintenance and energy optimization strategies can improve operations while ensuring employee well-being.

Tips for Energy Efficiency

- Leak detection and prevention: Air leaks not only waste energy but also reduce system pressure. Regularly inspect piping and connections for potential leaks.

- Optimize operating pressure: Running your system at unnecessarily high pressure can waste energy. Assess the minimum pressure needed for your operations.

- Use variable speed drives (VSDs): VSD-equipped compressors can adjust their speed based on demand, resulting in energy savings.

Safety Guidelines

- Regular maintenance: Keep equipment in top condition by scheduling routine check-ups. Filters and dryers should also be replaced as needed.

- Avoid misuse: Never directly blow compressed air onto skin or use it for tasks like cleaning clothes due to the potential risk of injury.

- Train employees: Ensure everyone operating the system knows how it works and understands basic safety measures.

By sticking to these guidelines, you can ensure your organization operates its compressed air equipment safely and efficiently.

Purchasing Versus Renting

When it comes to compressed air systems, businesses often face the decision between purchasing and renting. Here are some factors to consider:

Purchasing Compressed Air Systems

- Long-term investment: Purchasing a compressed air system can be a long-term investment, providing ownership and control over the equipment.

- Customization: Owning the system allows for customization to meet specific operational needs, ensuring optimal performance and efficiency.

- Cost efficiency: Over time, purchasing may be more cost effective compared to rental fees, especially for businesses with high and consistent compressed air demands.

Renting Compressed Air Systems

- Flexibility: Renting offers flexibility, allowing businesses to adjust their compressed air capacity based on fluctuating needs or short-term requirements.

- Maintenance and repairs: Renting typically includes maintenance and repair services, relieving businesses of the responsibility and costs associated with upkeep and unexpected breakdowns.

- Lower initial costs: Renting can be a more affordable option initially, as it eliminates the upfront investment typically required for purchasing a compressed air system.

Ultimately, the decision to purchase or rent a compressed air system depends on the specific needs and circumstances of each business.

The Future of Compressed Air Technology

The compressed air industry is evolving in exciting ways. Sustainability and cost efficiency are leading drivers for innovation. Here’s what’s ahead:

1. Energy-Efficient Compressors

Manufacturers are investing in more efficient machines that work harder while using less energy. Oil-free compressors are also gaining traction, especially in food and medical spaces.

2. Integration With Renewable Energy

Compressed air energy storage (CAES) systems store renewable energy as compressed air, making them a promising solution for a greener future.

3. Sensors and IoT

Digital monitoring solutions within the Internet of Things (IoT) now allow businesses to track their compressed air systems in real time, identifying leaks, inefficiencies, and opportunities for optimization.

With advancements like these, the role of compressed air is not only secure but likely to grow.

Take Control of Your Compressed Air Journey

Compressed air is a powerful tool that supports operations in nearly every industry. By learning everything you need to know about compressed air, you can maximize its efficiency while reducing your environmental impact.

Looking for quality air tanks that you can depend on to hold compressed air? At US Air Compressor, we offer solutions for every industry, giving you peace of mind from start to finish. Get more out of your compressed air equipment!