Choosing Pump Size and Air Tank Volume Proportions

Selecting the right components for a compressed air system is a critical task that directly impacts operational efficiency and longevity. A frequent question that arises during this process is how to correctly balance the pump size with the air tank volume. The relationship between these two components is fundamental to achieving a reliable and effective compressed air supply. Making an informed decision requires a thorough understanding of how each element functions and how they interact within the system. This guide will provide detailed information on the principles behind choosing pump size and air tank volume proportions to ensure your system operates at its peak potential. We will explore the various factors that influence this decision, offering a clear path to configuring a system that meets your specific demands with precision and dependability.

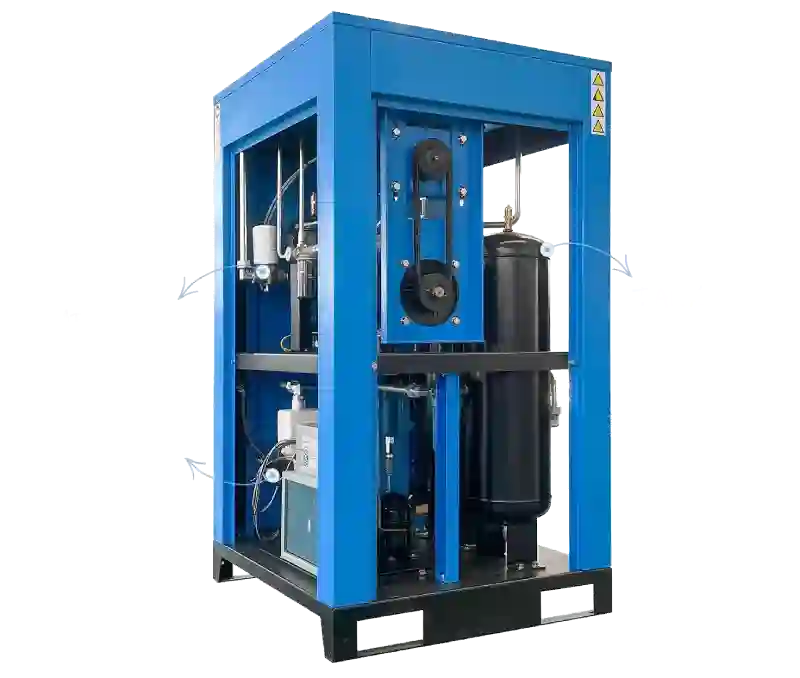

Understanding Pump Types and Their Functions

The pump, or compressor, is the core of the compressed air system, responsible for generating the pressurized air. Different types of pumps are available, each with distinct operating characteristics that make them suitable for particular applications. The primary categories are positive displacement and dynamic compressors. Positive displacement compressors, such as reciprocating and rotary screw types, work by trapping a volume of air and then reducing that volume to increase its pressure. Reciprocating compressors use pistons to compress air, making them a common choice for applications with intermittent demand. Rotary screw compressors use two intermeshing screws to compress air continuously, which is ideal for operations requiring a constant air supply. Dynamic compressors, like centrifugal compressors, increase air pressure by accelerating the air with a rotating impeller and then slowing it down. Understanding the operational mode of your chosen pump is the first step toward proper sizing.

The Process of Pump Sizing

Sizing a compressor pump correctly involves more than just selecting a horsepower rating. It requires a detailed assessment of your facility’s compressed air demand. The key metric for this assessment is cubic feet per minute, or CFM, at a specific pressure, measured in pounds per square inch, or PSI. To determine your required CFM, you must conduct an audit of all the tools, equipment, and processes that will use compressed air. Each pneumatic device has a specific CFM requirement at a designated PSI to function correctly. Summing up the requirements of all equipment that will operate simultaneously provides a baseline for your total demand. It is also important to account for future growth. A system that only meets current needs may quickly become inadequate as your operations expand. Therefore, including a buffer in your CFM calculation provides a margin for expansion and ensures the system remains capable over time.

The Role of the Air Receiver Tank

The air receiver tank serves multiple crucial functions within a compressed air system. Its most apparent role is to store compressed air, creating a buffer that can be drawn upon during periods of high demand. This storage capacity helps stabilize the pressure within the system, preventing rapid fluctuations that could affect the performance of air-powered equipment. Beyond storage, the tank also plays a significant part in cooling the compressed air and allowing moisture and oil to condense and separate out. As hot, moist air from the compressor enters the cooler tank, its temperature drops, causing water vapor to turn into liquid. This condensate can then be drained from the bottom of the tank, improving the quality of the air delivered to your tools and processes. The tank also smooths out the pulsations from the compressor, particularly with reciprocating models, resulting in a more consistent flow of air. The effective use of air tanks is essential for system stability.

Balancing Pump and Tank Volume

The core of choosing pump size and air tank volume proportions lies in understanding the interplay between compressor output and storage capacity. An improperly sized tank can lead to significant operational issues. If the tank is too small for the compressor’s output, the compressor will cycle on and off frequently. This short cycling increases wear and tear on the motor and other components, leading to premature failure and higher maintenance costs. It also results in greater energy consumption, as starting the motor requires a significant inrush of current. Conversely, a tank that is excessively large for the pump’s capacity can also be inefficient. While it will reduce cycling, the compressor will need to run for extended periods to fill the tank, which may not be optimal for its duty cycle. An oversized tank also takes up valuable floor space and represents an unnecessary capital expense.

Determining Optimal Proportions

A general guideline for sizing a receiver tank is to allow for 1–3 gallons of tank volume for every CFM of compressor output. For example, a compressor rated at 20 CFM would ideally be paired with a tank between 20 and 60 gallons. However, this is a starting point, and the specific application should guide the final decision. For systems with highly variable or intermittent demand, a larger tank is often beneficial. The larger storage volume can accommodate sudden peaks in usage without requiring the compressor to start immediately, thus reducing cycling and energy use. For applications with a steady, continuous demand, the tank’s role as a buffer is less critical, and a smaller tank, perhaps one gallon per CFM, might be sufficient. The goal is to size the tank to allow the compressor to operate within its recommended duty cycle, which is the percentage of time it can run without overheating.

A More Reliable System

Properly balancing the pump size and air tank volume is not an arbitrary exercise; it is a fundamental aspect of designing a reliable and efficient compressed air system. A well-proportioned system ensures a consistent supply of compressed air at a stable pressure, protects the compressor from excessive wear, and minimizes energy consumption. By carefully analyzing your air demand, understanding the operational characteristics of your compressor, and applying established sizing principles, you can configure a system that delivers dependable performance. This considered approach to system design will yield long-term benefits in the form of lower operating costs, reduced maintenance, and enhanced productivity for your entire facility.