Benefits of Considering Backup Compressors

Efficiency and reliability are critical drivers for any operation relying on compressed air systems. Equipment failures and unplanned downtime can disrupt business, impact productivity, and create unnecessary stress for facilities managers. Therefore, organizations must invest in robust solutions that minimize risk and maximize uptime to ensure continuity. Explore the benefits of considering backup compressors to learn why this investment is essential for anyone who demands consistency and quality in their compressed air supply.

Ensuring Uninterrupted Operations

Unplanned downtime in compressed air delivery can halt entire production lines, and any interruption can slow output and compromise product quality. Facility managers often depend on at least one primary compressor to maintain air supply, but even the most durable systems are not immune to wear or malfunction.

When you add backup compressors to your setup, you create an immediate line of defense. If your main unit needs repairs or maintenance, a backup can take over. This setup keeps operations running smoothly, offering a safeguard against disruptions from equipment issues.

Switching to a backup solution provides peace of mind for leadership, maintenance teams, and operators. The switch is seamless, so there is never a loss of pressure that could affect tools, instruments, or manufacturing processes. Scheduled maintenance or repair activities become manageable because you know that essential systems remain active, backed by second-line support.

Protecting Productivity and Quality

Manufacturing environments, hospitals, food processing plants, and laboratories all rely on precise, consistent air pressure. Pressure drops or full outages can lead to spoiled products, wasted materials, or disrupted clinical workflows. An emergency replacement or a rushed repair may not meet the skill or quality standards that daily operation requires.

Having a backup compressor means you do not risk sudden interruptions that could jeopardize your standards for quality and productivity. Maintaining consistent compressed air means that automated machinery runs reliably, reducing the risk of costly batch failures or service delays. This reliability helps organizations meet delivery schedules, avoid penalties, and protect their reputation.

Downtime can put company revenue and contractual commitments in jeopardy, but a backup system preserves business continuity by taking on the load at a moment’s notice. Instead of halting workflows, companies transition seamlessly between compressors, always meeting production targets.

Extending Equipment Lifespan

Constantly running a compressor at full capacity places it under stress, leading to faster wear and a higher chance of breakdowns. Backup compressors allow you to take a more strategic approach to equipment use. By alternating between units or operating them in tandem, you can distribute operational loads evenly and prevent overwork.

This rotational method optimizes maintenance schedules and extends the useful life of primary equipment. Running compressors intermittently means each spends less overall time in service. Fewer machine hours per compressor translates to lower maintenance costs, reduced repair needs, and a decline in risk for catastrophic failure.

The presence of backup compressors also helps managers avoid running machinery past recommended service intervals. It becomes possible to schedule regular inspections, cleaning, and minor repairs during planned downtimes rather than delaying maintenance out of fear of disrupting operations.

Improving Safety and Regulatory Compliance

Industrial operations involving compressed air must adhere to strict safety codes and regulatory standards to protect personnel and infrastructure. Pressure fluctuations or abrupt system failures can create hazardous conditions, making backup solutions critical from a compliance perspective.

Backup compressors add a layer of security that is vital for maintaining compliance during inspections or audits. They ensure continuous adherence to process requirements set by occupational health and safety authorities and those specified by industry certification boards. For example, fire suppression systems powered by compressed air must always be online, and any outage could compromise insurance coverage or regulatory standing.

Furthermore, backup systems reduce the risk of operator exposure to high-pressure alarms, leaks, equipment surges, or malfunctions that might occur during an unplanned outage. Ensuring uninterrupted service keeps environments safer for workers, meeting both legal and moral obligations.

Reducing Operational and Emergency Costs

Downtime impacts go well beyond lost production hours. Companies facing equipment failure must often rely on expensive emergency repair services, expedited shipping for replacement parts, and in some cases, rental equipment. These costs quickly add up and can strain budgets.

Using backup compressors mitigates the financial risk by lowering dependency on emergency interventions. Regular, planned maintenance becomes feasible because production does not need to come to a halt for repairs. Backup solutions also eliminate the need for last-minute outsourcing or reliance on costly temporary compressors.

These cost benefits are magnified by preventing lost batches, defective products, or the need to issue refunds when compressed air systems go offline. When critical equipment is always supported by backup, operational budgets become more predictable and financial planning improves.

Enhancing Flexibility and Scalability

Business growth or shifting operational demands can challenge the capacity of a single air compressor system. Installing backup compressors early on creates a foundation for future expansion without significant disruption.

Facilities with modular backup configurations adapt more quickly to increased workloads, new production lines, or the integration of advanced machinery. Instead of replacing existing compressors with larger models, which may not be cost-effective, companies simply bring backup systems online or redistribute air flows for optimal output.

Backup compressors offer flexibility not only for growth but also for temporary shifts in business activity levels. If a site needs to ramp up order delivery during a busy season or special projects, a backup framework supports higher capacity without overloading equipment.

Strengthening Warranties, Guarantees, and Support Relationships

Reputable suppliers and manufacturers often link their most comprehensive warranties and guarantees to proper system installations, which almost always recommend or require backup solutions. Using backup compressors signals to technical support teams that your organization prioritizes reliability and operational best practices.

Suppliers and service providers confidently extend exchange warranties and thorough maintenance contracts to companies that invest in full compressor packages, including essential backup installations. This commitment to quality ensures that support response is fast, specialized, and focused on long-term partnership. Having backup compressors allows organizations to maximize coverage under warranty or support agreements while reinforcing their reputation as prepared and effective operators.

Integrating Backup Compressors

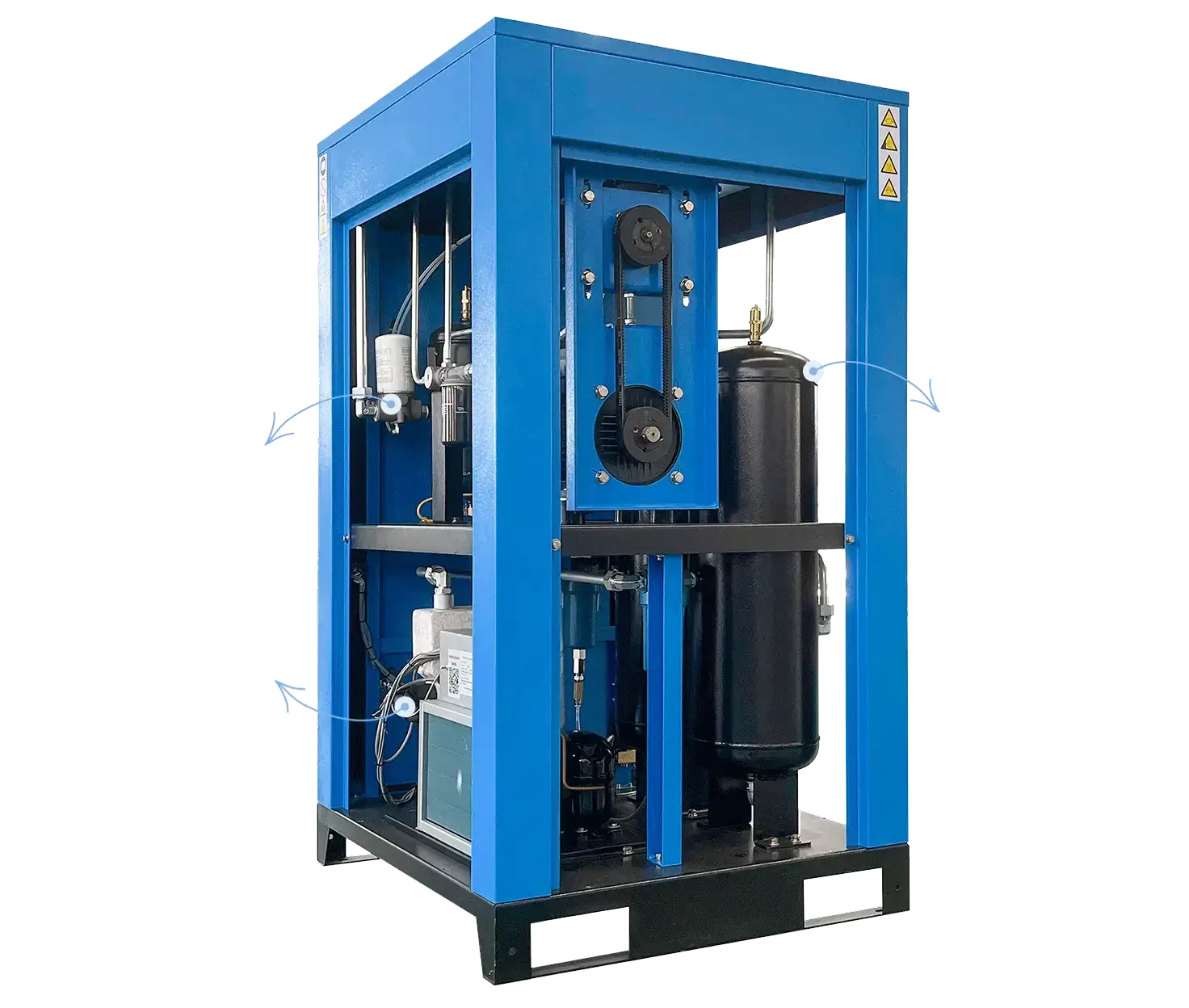

Integrating backup compressors as part of a comprehensive air compressor package secures the greatest value for your investment. It aligns the benefits of redundancy with the technical and service commitments of industry leaders. When an air compressor package is designed for reliability, downtime risks are minimized and operational excellence becomes the norm.

Optimized packages simplify procurement and installation while streamlining maintenance agreements. Combined with industry-leading warranty coverage, backup compressors guarantee peace of mind and operational certainty that can withstand audit scrutiny and market pressures.

The Critical Investment in Backup Compressors

Organizations seeking efficiency must balance productivity, safety, and operational flexibility. System redundancy through backup compressors is a practical investment that delivers reliability at every turn. The benefits of considering backup compressors become the foundation for successful business operations, from reducing costs to increasing uptime and facilitating future growth.

Backup compressors allow businesses to maintain full control over air quality and availability, no matter the challenges. Investing in backup technology means investing in superior outcomes, customer satisfaction, and the long-term value of your asset base.