A Guide to Sizing Your Air Compressor’s Piping System

The size of your air compressor’s piping system is the foundation of a reliable and efficient setup. Missteps in design or installation could lead to pressure drops, reduced performance, and wasted energy. This guide walks you through the considerations for sizing your air compressor’s piping system so that it delivers consistent and efficient performance.

This comprehensive guide to sizing your air compressor’s piping system ensures you don’t overlook any aspect of your system. Whether you are planning an entirely new installation or upgrading an existing setup, you will gain valuable insights into delivering optimal airflow.

Understanding the Importance of Piping System Sizing

The piping system for an air compressor maintains consistent pressure and maximizes the system’s efficiency. Improperly sized or poorly designed piping can lead to pressure drops, reduced functionality of air-powered tools, and operational inefficiencies. This is particularly relevant in professional and industrial environments where compressed air is a critical component of daily operations.

The key objective of sizing your air compressor’s piping system is to minimize pressure loss between the compressor and the point of use. Efficient air delivery requires balancing factors such as piping diameter, length, and material type.

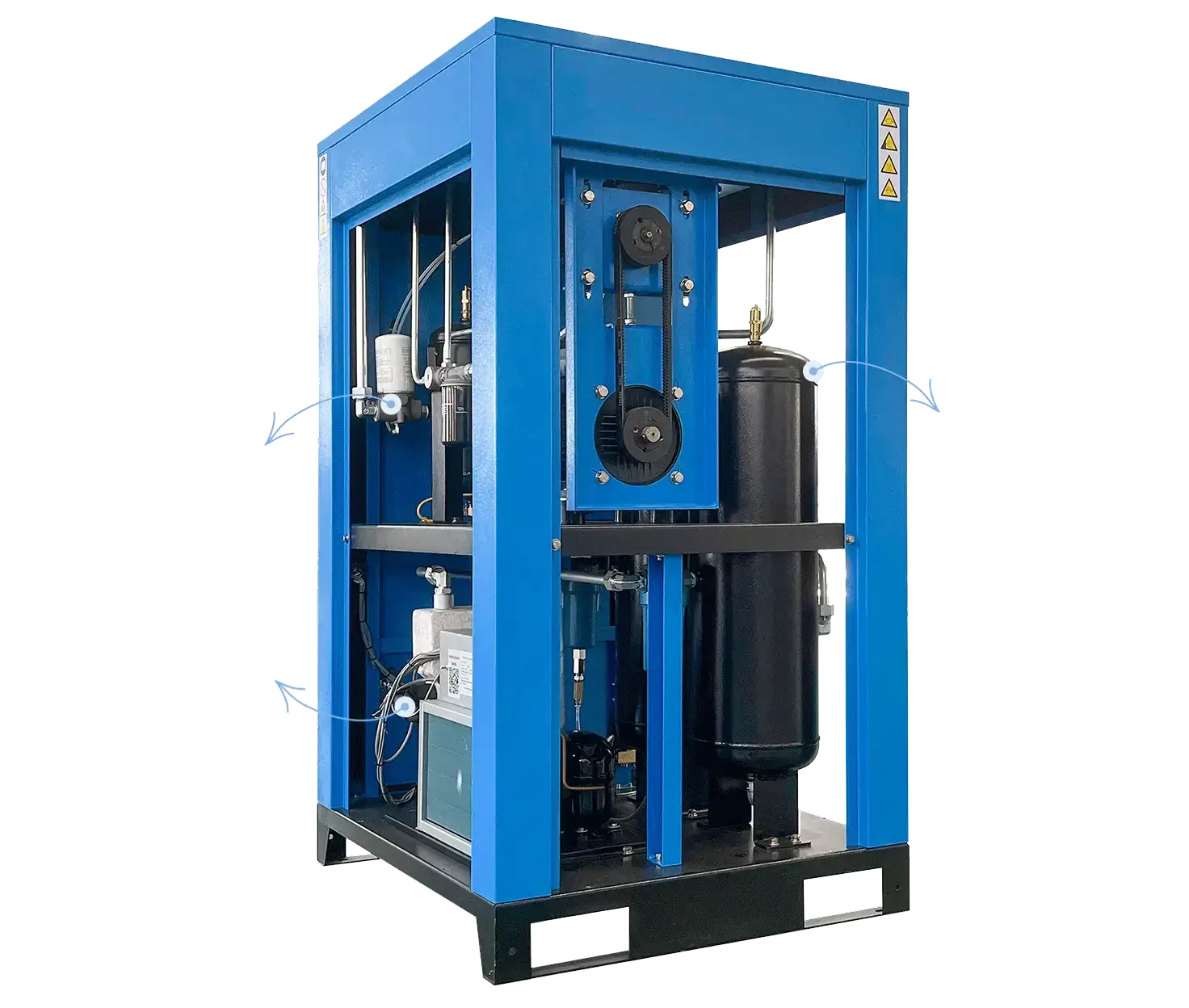

By focusing on these elements, you can minimize downtime, extend the working life of your equipment, and prevent disruptions to your operations. With the right configuration, air tanks for compressors can support seamless performance across your facilities.

Identifying Your System’s Initial Requirements

Before beginning the design process for your air compressor’s piping system, determine the expected flow rate and pressure levels for your system. These operational parameters directly influence the appropriate size and type of piping.

The flow rate is measured in cubic feet per minute (CFM) and determines the amount of compressed air your system needs to deliver to all points of use. The pressure, typically measured in pounds per square inch (psi), determines the amount of force available for the tools and equipment powered by the system.

Anticipate periods of peak demand. Some facilities experience variable compressed air usage across different shifts or tasks. Designing your system to manage maximum demand levels ensures that you maintain reliability during operations.

Finally, include air tanks for compressors as part of your planning to act as storage buffers. Considering these components during the system-sizing phase will stabilize pressure and provide additional capacity for sudden spikes in demand.

Evaluating the Role of Pipe Diameter

Selecting the correct pipe diameter is one of the most impactful decisions in sizing your air compressor’s piping system. Many professionals make the mistake of underestimating how much pressure can be lost through undersized piping. Even if the compressor is rated to produce sufficient air pressure at the source, small pipe diameters can struggle to deliver air efficiently to multiple locations or over long distances.

The internal diameter of pipes determines the amount of air that can flow through them at any given time. Pipes with large diameters enable high air volume with minimal resistance, greatly reducing the risk of pressure drops. However, oversized pipes can also pose challenges, as they may add unnecessary costs to your system.

To strike the perfect balance, calculate the minimum diameter required based on the flow rate, pressure, and the total length of the piping. For complex layouts, including branches and multiple endpoints, the sizing calculation must account for additional factors, such as pressure losses at bends, valves, and filters.

Choosing Suitable Piping Materials

The piping material also influences the system’s performance, reliability, and lifespan. The two most common materials in industrial-grade air compressor piping systems are metal and plastic, each with advantages and limitations.

Metal piping, such as galvanized steel or aluminum, offers durability and resistance to wear. While steel is popular for heavy-duty applications, its heavy weight and susceptibility to rust can pose challenges in maintenance. Aluminum piping, on the other hand, is lightweight, corrosion-resistant, and easy to install, making it ideal for facility managers seeking to lower maintenance costs.

Plastic piping, such as reinforced nylon or ABS, are cost-efficient and easy to handle. However, plastic is typically better suited for low-pressure applications or where flexibility is a necessity. The materials must align with the psi and temperature levels of the compressor’s operations.

Accounting for System Layout and Length

Beyond pipe sizing and materials, the physical layout of your piping network plays a role in operational efficiency. The goal should be to design a layout that minimizes air travel distance and reduces bends, angles, or obstructions.

Straight runs produce the least resistance and are ideal whenever feasible. When bends and turns are unavoidable, use gradual curves rather than sharp angles to preserve pressure levels. In addition, avoiding excess fittings and connectors not only supports pressure retention but also lowers the risk of air leaks.

For large or multi-level facilities, divide your system into zones based on demand and usage patterns. Installing pressure regulators or flow switches at key junctions can maintain consistent performance throughout the entire network. Additionally, check pipe supports, thermal expansion allowances, and vibration isolation measures.

Maintenance and Long-Term Performance Considerations

Consistency in performance demands routine maintenance and monitoring of your air compressor’s piping system. Over time, even the best systems can experience wear, rust accumulation, or unscheduled leaks. Incorporating fittings that support easy inspection and sectional shut-off valves can simplify maintenance tasks and minimize downtime.

Using air tanks for compressors not only adds storage capacity but also stabilizes pressure during demanding applications. These tanks act as reservoirs, preventing fluctuations in demand from causing interruptions. Including appropriately sized tanks can relieve strain on both the compressor and the piping system.

Finally, invest in real-time monitoring systems to track pressure, flow rates, and potential faults in the network. Today’s advanced solutions provide immediate alerts for any discrepancies, allowing for timely interventions before they escalate into larger operational challenges.

Ensuring Efficiency and Reliability In Your Air Compressor Setup

A well-sized air compressor piping system is fundamental for achieving maximum productivity and minimizing disruptions in industrial settings. By addressing the factors in this guide to sizing your air compressor’s piping system, you can create a piping system that meets the demands of your operations.

Properly implemented systems efficiently deliver air where it is needed most, whether powering tools, equipment, or other applications. By including air tanks for compressors and proactively considering future scalability, your setup will remain reliable as your facility grows.

Assess your unique requirements, and plan carefully. You’ll not only improve day-to-day performance but also extend the lifespan of your air compressor equipment.