Managing Air Compressor Noise and Hearing Protection

Facilities across the manufacturing, automotive, and construction industries rely heavily on compressed air systems for daily operations. While these systems provide essential power for tools and machinery, they also generate significant noise levels that can pose serious risks to worker health and safety.

Understanding when to manage sound levels and how to implement proper hearing protection measures is crucial for maintaining a safe and productive work environment. This post on managing air compressor noise and hearing protection will review protection protocols to prevent permanent hearing damage for workers, an uncomfortable working environment, and reduced productivity and morale.

Health Risks of Prolonged Noise Exposure

Exposure to high noise levels from industrial equipment can lead to gradual hearing deterioration that may not be immediately noticeable but becomes permanent over time. Workers may experience tinnitus, a constant ringing or buzzing in their ears that can persist even after leaving the noisy environment.

Beyond hearing damage, excessive noise exposure can cause increased stress levels, fatigue, and difficulty concentrating. These effects can impact worker performance, increasing the likelihood of accidents and reducing overall job satisfaction.

Physical symptoms may include headaches, elevated blood pressure, and sleep disturbances for workers who experience prolonged exposure to high noise levels. The cumulative effects of these health impacts reduce worker well-being and productivity, making noise management a priority for responsible facility management.

Effective Noise Reduction Strategies

Managing air compressor noise and hearing protection requires implementing effective noise reduction strategies. First, you need a comprehensive approach that addresses the source of the noise and the environment where it operates.

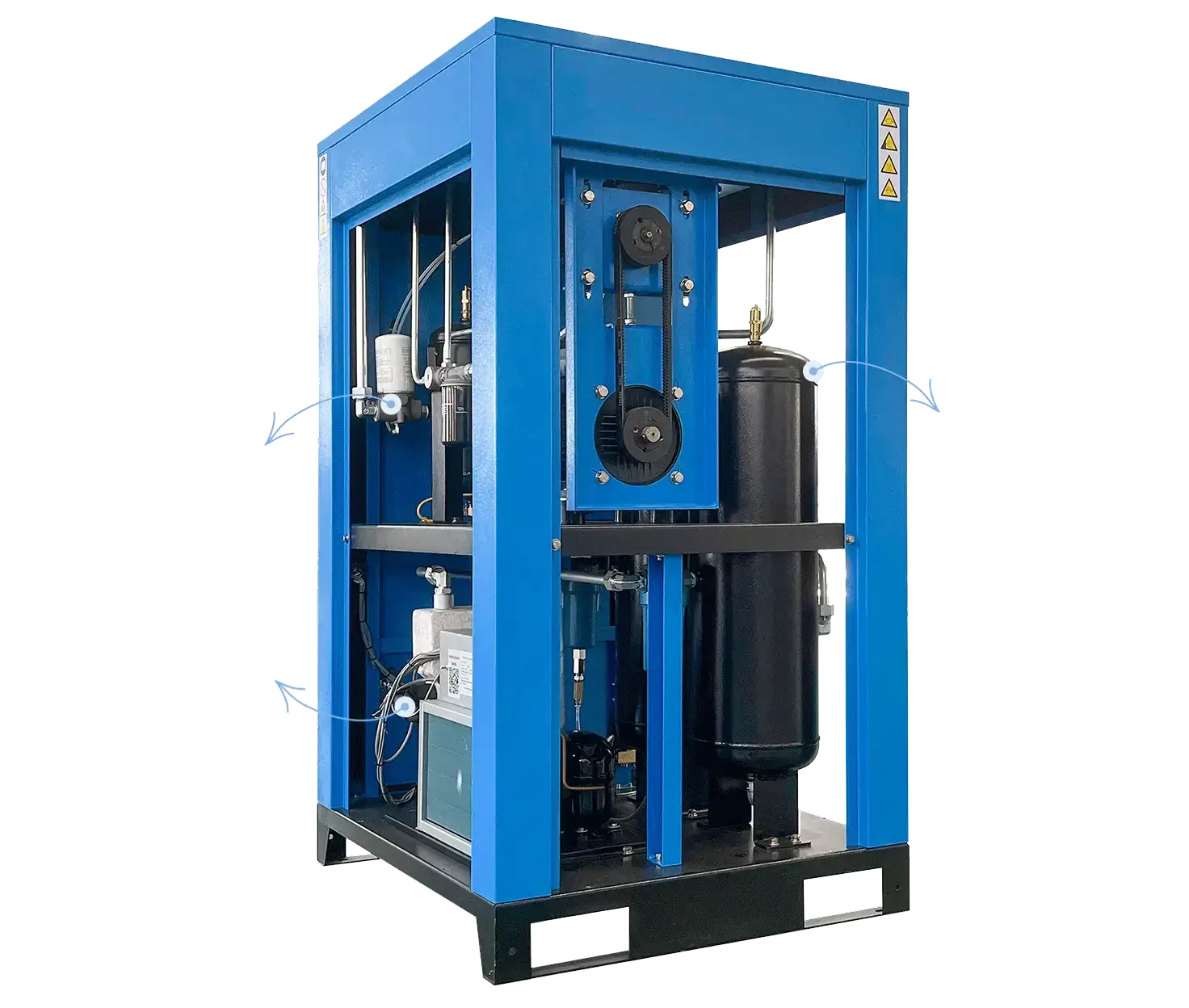

Sound enclosures are one of the most effective methods for containing compressor noise. These enclosures can be custom-designed to fit specific equipment while providing access for maintenance and operation.

Strategic compressor placement in dedicated rooms or areas separated from main work zones can substantially reduce noise exposure for most workers. These dedicated spaces may include sound-absorbing materials on walls and ceilings to further reduce noise levels. Proper ventilation must be maintained in these enclosed spaces for adequate cooling and air circulation.

Vibration isolation systems can also reduce the transmission of noise through building structures. Installing compressors on vibration-dampening pads or springs prevents mechanical noise from traveling through floors and walls to other areas of the facility. Regular maintenance allows for the replacement of worn components, which often produce higher noise levels, before they contribute to excessive sound generation.

Selecting Appropriate Hearing Protection Equipment

Choosing the right hearing protection requires careful consideration of the specific noise levels present in the work environment and the tasks workers need to perform. Foam earplugs offer basic protection and are suitable for environments with moderate noise levels. These disposable options are cost-effective and easy to use but may not provide sufficient hearing protection in extremely high-noise environments.

Silicone or premolded earplugs provide better durability and consistent protection levels. Custom-molded earplugs, created from impressions of individual workers’ ears, offer superior comfort and protection for workers who require hearing protection for extended periods. These custom options offer a proper fit and maximum effectiveness while allowing for comfortable long-term wear.

Earmuffs are an alternative or supplementary option that can be easily put on and removed as needed. Some earmuff designs incorporate communication capabilities, allowing workers to connect effectively while maintaining their hearing protection. Electronic earmuffs can amplify low-level sounds while automatically reducing harmful noise levels, providing better protection and situational awareness.

Implementing Comprehensive Hearing Conservation Programs

A successful hearing conservation program requires more than simply providing hearing protection equipment. Regular hearing assessments establish baseline measurements and monitor changes in worker hearing ability over time. Qualified professionals should conduct and document these assessments to track trends and identify potential issues early.

Training programs help workers understand the importance of hearing protection and how to use the provided equipment properly. This training should cover proper insertion techniques for earplugs, reusable equipment maintenance, and recognition of situations that require hearing protection. Workers should also understand the health risks associated with noise exposure and their role in maintaining a safe work environment.

Managing air compressor noise and hearing protection requires ongoing monitoring and adjustment of protection measures. Regular noise level measurements identify areas where additional protection may be needed and verify the effectiveness of implemented noise reduction strategies. Documentation of these measurements provides valuable data for regulatory compliance and continuous improvement efforts.

Maintenance and Monitoring for Long-term Success

Air compressor machines with worn or poorly maintained components often produce higher noise levels than those with well-maintained components, making regular maintenance a crucial factor in noise control.

Effective noise management requires ongoing attention to equipment maintenance and environmental monitoring. Regular inspection of compressor components identifies worn parts that may contribute to increased noise levels. Lubrication schedules, belt tension adjustments, and replacing worn components all contribute to maintaining optimal noise levels.

Monitoring systems can provide continuous feedback on noise levels throughout the facility, alerting management to changes that may require attention. These systems can identify when maintenance is needed or when additional protection measures should be implemented in specific areas.

Worker feedback provides valuable insights into the effectiveness of hearing protection programs and noise reduction measures. Regular surveys or informal discussions can reveal comfort issues with protection equipment, areas where noise levels remain problematic, or suggestions for improvement that may not be apparent through technical measurements alone.

Creating a Safer and More Productive Work Environment

Effective noise management and hearing protection create benefits that extend throughout the entire facility. Reduced noise levels improve communication between workers, decrease stress, and create a more pleasant working environment. These improvements often lead to increased productivity, reduced turnover, and enhanced worker satisfaction.

Implementing comprehensive noise management strategies demonstrates a commitment to worker safety and health, which can improve a company’s reputation and attract high-quality employees. Proper hearing conservation programs also comply with occupational safety regulations, reducing the risk of penalties and legal issues related to workplace safety.

Investing in noise reduction and hearing protection measures typically yields returns through improved worker health, increased productivity, and reduced liability risks. By taking a proactive approach to managing compressor noise and protecting worker hearing, facilities can create safer, more efficient operations that benefit employees and the organization as a whole.