Debunking Common Myths About Rotary Screw Air Compressors

Air compressors play an essential role in a variety of industries, driving productivity and innovation across all sorts of different applications. Among the many compressor types available, rotary screw air compressors stand out due to their reliability and versatility. Yet despite their widespread use, misconceptions about these machines persist. Unfortunately, these myths can discourage businesses from fully understanding or utilizing the immense benefits of rotary screw compressors.

To set the record straight, we’re debunking these common myths about rotary screw air compressors. From addressing misconceptions about their efficiency to clearing up concerns about cost and maintenance, we’ll uncover the truth and highlight why rotary screw air compressors might be just the right choice for your business.

What Are Rotary Screw Air Compressors?

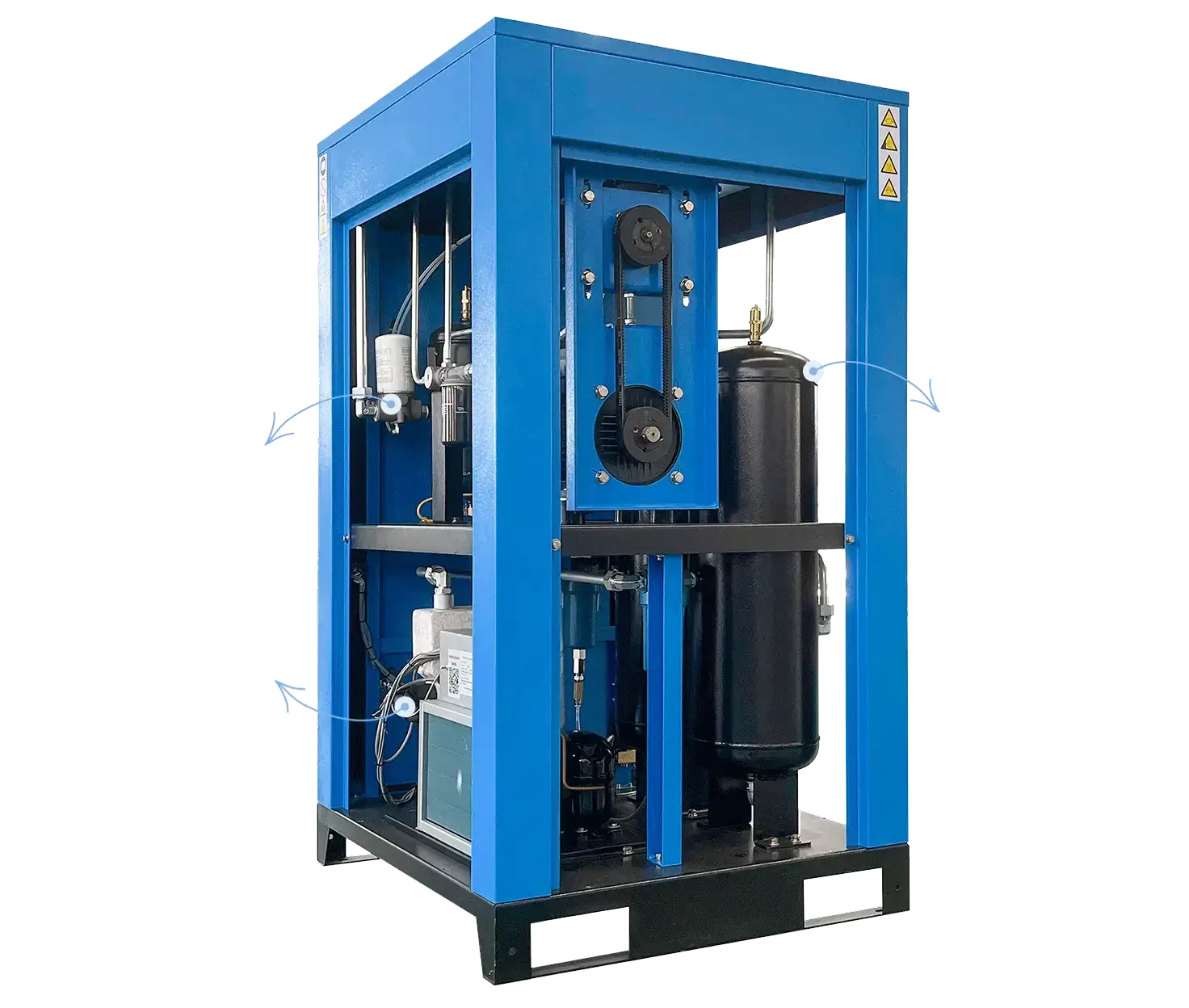

Before tackling the myths, it’s important to understand what rotary screw air compressors are and how they work. These machines use two rotating screws (rotors) to compress air. As the screws rotate, air gets trapped between them, then compressed to the desired pressure before being released.

Because of their design, rotary screw air compressors operate continuously, making them ideal for applications that require constant airflow. They’re energy-efficient, versatile, and capable of delivering high-performance results in demanding environments. This combination of functionality and efficiency is why rotary screw air compressors are a favorite in many industries.

How Do They Differ From Other Compressors?

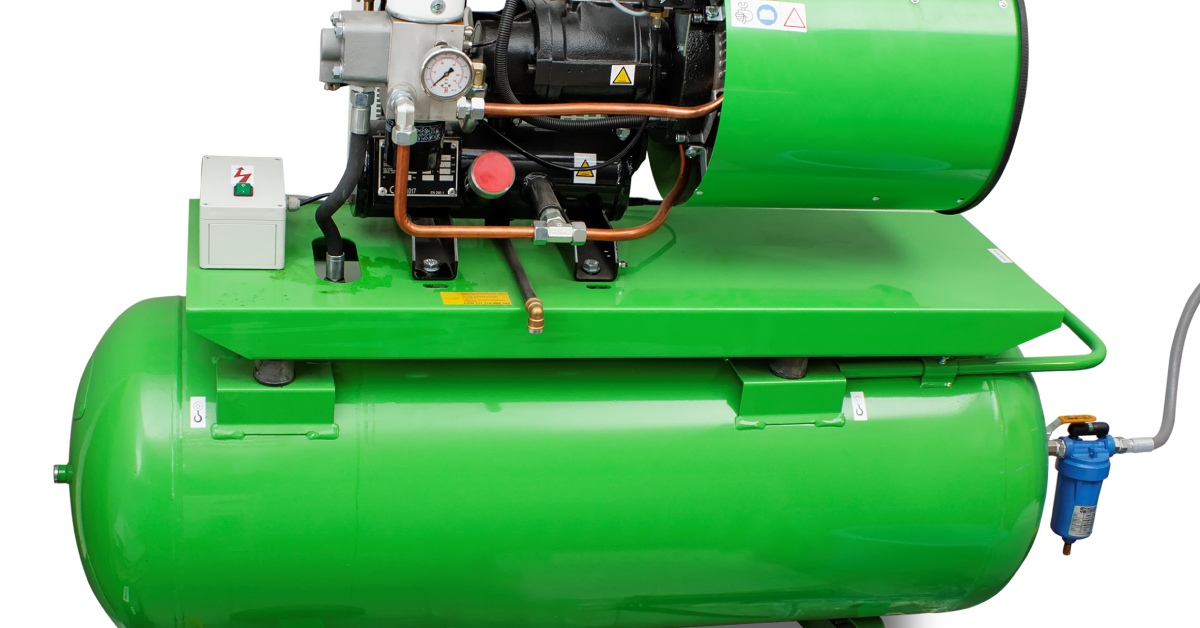

Unlike piston compressors that use a cylinder and piston to compress air in pulses, rotary screw compressors provide a smooth, steady stream of air. These compressors also require less maintenance due to their fewer moving parts. Further, rotary screw air compressors are designed for long-term usage, making them an attractive option for businesses that rely on continuous operation.

Industries That Use Rotary Screw Air Compressors

Rotary screw air compressors form the backbone of many industries. Here’s a closer look at some key sectors and how they leverage these powerful machines:

- Manufacturing: Businesses rely on rotary screw air compressors to power pneumatic tools, conveyor belts, and automated machinery.

- Food and beverage: Rotary screw compressors provide clean, contaminant-free compressed air for packaging, bottling, and food processing.

- Construction: Construction businesses find these compressors essential for running heavy-duty tools like jackhammers, drills, and sandblasters.

- Health care: Thanks to rotary screw air compressors, health care facilities have a sterile air supply for ventilators and other medical equipment.

- Automotive: Assembly lines, tire inflation, and painting booths all rely on the power of these compressors.

- Energy and power generation: Rotary screw air compressors support operations in refineries, power plants, and renewable energy projects.

Debunking Rotary Screw Air Compressor Myths

It’s time to address misconceptions about rotary screw air compressors with facts. Here’s what you need to know.

Myth 1: Rotary Screw Compressors Are Less Efficient Than Other Types

Rotary screw air compressors are among the most energy-efficient available. Their design minimizes energy losses and provides continuous airflow without the frequent starts and stops characteristic of piston compressors. Additionally, modern compressors come equipped with variable speed drives (VSDs), which adjust the motor’s speed based on air demand, further reducing energy consumption.

Myth 2: Screw Compressors Are Noisy and Not Suitable for Indoor Use

While earlier models may have been loud, advancements in technology have made modern rotary screw compressors much quieter. Many now feature soundproofed enclosures, allowing for near-silent operation, even when placed indoors. This trait makes these compressors suitable for environments where noise reduction is a priority, including workshops and health care facilities.

Myth 3: They’re Too Expensive To Operate and Maintain

Rotary screw compressors are designed to be cost-effective in the long run. Their fewer moving parts mean less wear and tear, which translates to lower maintenance costs compared to piston compressors. Additionally, their energy-efficient operation can reduce electricity bills, making these compressors a smart investment over time.

Myth 4: Screw Compressors Are Only for Large Industrial Applications

While rotary screw compressors are widely used in large-scale industrial applications, they’re also available as smaller units designed for light and medium-duty usage. Small businesses, workshops, and medical facilities can all benefit from compact models tailored to their airflow requirements without compromising efficiency or reliability.

Myth 5: They’re Difficult To Install and Require Extensive Maintenance

Rotary screw compressor installation is straightforward, and many models are now designed as plug-and-play systems. Maintenance is minimal, focusing on routine tasks like changing filters and checking lubricant levels. Modern designs emphasize user-friendly components, enabling operators to maintain their compressors with ease.

The Benefits of Rotary Screw Air Compressors

Now that we’ve cleared up the myths, it’s time to focus on why rotary screw air compressors are a valuable addition to any business.

Energy Efficiency

Rotary screw compressors are built for efficiency, allowing businesses to reduce energy costs while maintaining consistent airflow. Features like VSDs and advanced cooling systems enhance performance.

Reliability

The robust design of rotary screw air compressors provides a long lifespan with minimal downtime, even under demanding conditions. Unlike other compressors that struggle with high-duty cycles, rotary screw machines thrive in 24/7 operations.

Low Maintenance

Fewer moving parts mean there’s less that can go wrong. Maintenance tasks are simple and infrequent, making these compressors highly practical for busy operations.

Versatility

From powering construction tools to packaging delicate foods, the adaptability of rotary screw compressors is unparalleled.

Quiet Operation

Thanks to sound-dampening technology, modern compressors operate at noise levels that are friendly to workers and the general environment.

Longevity

Rotary screw compressors are built to last, often outliving other types of air compressors when properly maintained. This durability makes them a reliable long-term investment.

Maintenance Tips for Rotary Screw Air Compressors

To ensure optimal performance and longevity of your rotary screw air compressor, consider the following maintenance tips:

- Regular inspection: Conduct periodic inspections of the compressor’s components, including belts, filters, and oil levels, to identify and address potential issues promptly.

- Proper lubrication: Follow the manufacturer’s guidelines for lubrication to maintain smooth operation and prevent excessive wear and tear. Regularly check and change the compressor oil as recommended.

- Air filter cleaning and replacement: Clean or replace air filters regularly to prevent dust and debris from clogging the system.

- Condensate drainage: Regularly drain the condensate from the compressor’s air receiver tank to prevent moisture buildup that can lead to corrosion and damage.

- Cooling system maintenance: Keep the cooling system clean and free from debris to prevent overheating. Regularly inspect and clean the heat exchangers and fans for optimal cooling efficiency.

- Professional servicing: Schedule regular professional servicing to perform more in-depth inspections, maintenance, and troubleshooting to keep your compressor operating at its best.

Why You Should Consider a Rotary Screw Air Compressor

If you’re looking for a dependable, efficient, and versatile air compressor, rotary screw models should be at the top of your list. By debunking common myths about rotary screw air compressors, it’s clear that these compressors offer unparalleled value for businesses of all sizes and industries. Whether you’re running a manufacturing plant, managing a health care facility, or operating a construction site, you can elevate your operations with a rotary screw air compressor.

Are you ready to experience the benefits of rotary screw designs for yourself? At US Air Compressor, we offer a variety of solutions to meet your needs. Our wide selection of air compressors is sure to have something for you!