Shared vs Separate Compressors: Which Is Right for You?

One of the fundamental decisions you must consider involves choosing between a shared or separate configuration when choosing the right air compressor system for your facility. This choice carries significant implications for operational efficiency, maintenance, and long-term costs. A shared system, also known as a centralized system, involves one or more large compressors serving multiple applications throughout a facility.

A separate, or decentralized, system utilizes smaller, individual compressors located at or near the point of use for specific tasks. Understanding the distinct characteristics of each approach is essential for making an informed decision that aligns with your specific industrial requirements and operational goals. Determining whether a shared or separate compressor setup is right for you requires a detailed assessment of your facility’s layout, demand patterns, and performance expectations.

Understanding Shared Compressor Systems

A shared compressor system centralizes the production of compressed air in one dedicated location. A network of pipes distributes the air to various points of use across the facility from this central point. Many larger operations favor this configuration, as compressed air is a critical utility for numerous processes.

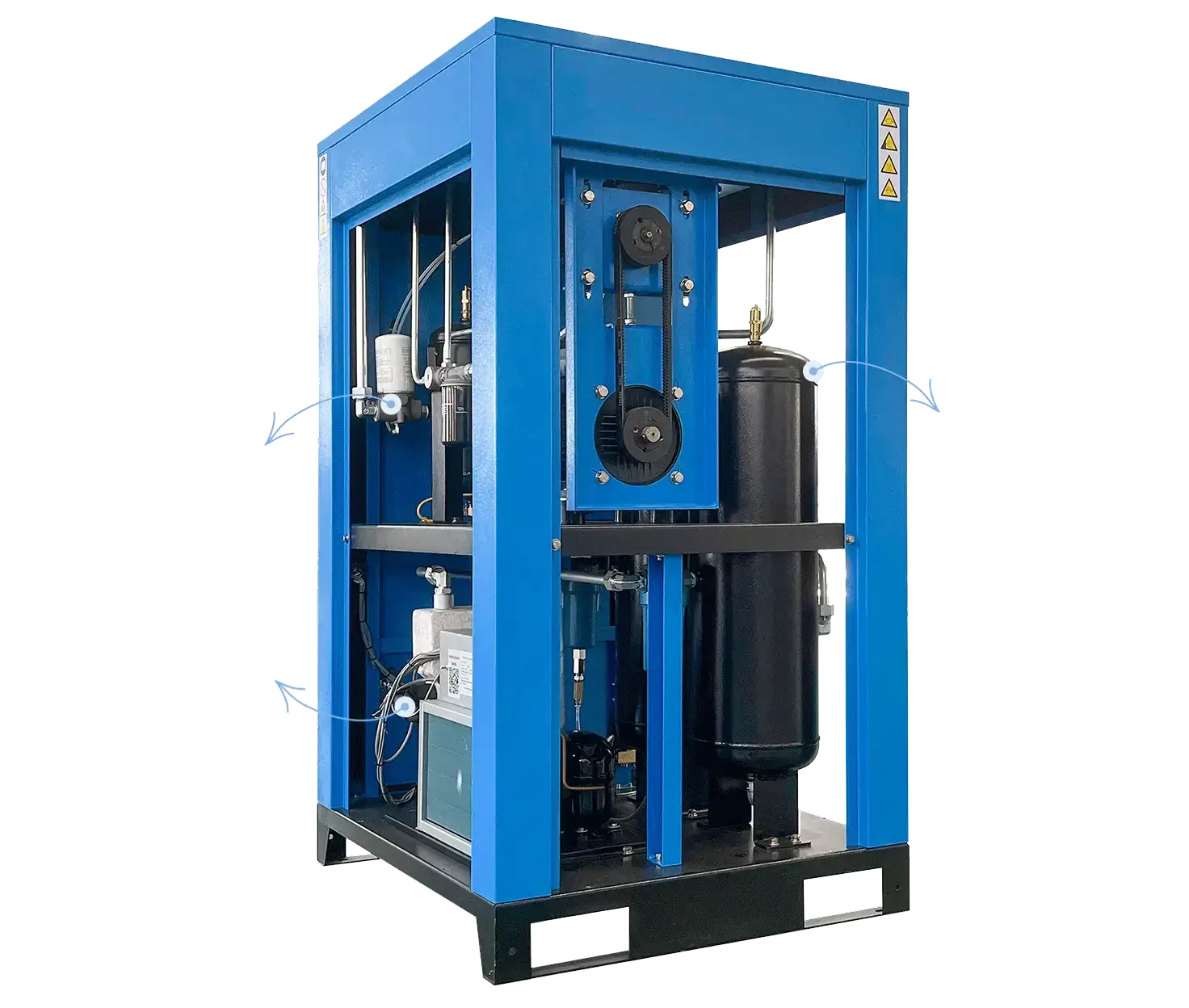

The primary advantage of a shared system is the potential for greater energy efficiency, as larger compressors often operate more efficiently than multiple smaller units. You can streamline maintenance routines by consolidating equipment into a single room, making it simpler for technicians to service and monitor the equipment without disrupting plant-wide operations. This centralized approach also allows for more effective management of air quality through integrated dryers and filtration systems that treat all the air before it enters the distribution network.

You can scale a centralized system by adding more compressors to the main bank, providing a clear path for expansion as production demands grow over time. However, a shared system is not without its challenges. The extensive piping required can be a significant source of energy loss if not properly designed and maintained.

Leaks in the distribution network can lead to substantial waste, increasing operational costs, and placing a greater load on the compressors. The initial investment for a centralized system, including the cost of large compressors and the installation of a comprehensive piping network, can also be considerable. Furthermore, the entire facility’s compressed air supply is dependent on the central system.

If a major failure occurs, it could result in a complete shutdown of all operations that rely on compressed air, highlighting the need for built-in redundancy, such as a backup compressor. Pressure drops can also be a concern in large facilities, as the air must travel long distances from the compressor room to the point of use, potentially affecting the performance of end-use equipment.

Examining Separate Compressor Systems

A separate, or decentralized, compressor system involves placing smaller, dedicated compressors directly at the points where compressed air is necessary. This point-of-use approach eliminates the need for an extensive and complex piping network, which can be a significant advantage in certain operational contexts. The reduction of energy losses associated with long pipe runs and air leaks is one of the primary benefits of a separate system.

The compressor located close to the application delivers air at a more consistent pressure, which can improve the performance and efficiency of the tools and equipment it powers. This configuration provides a high degree of flexibility, as you can select individual compressors to meet the specific pressure and flow requirements of each application. For instance, a process requiring high-pressure air can have its own dedicated compressor, while a different, appropriately sized unit can serve another process with lower requirements.

The decentralized model also offers enhanced reliability. Since each application has its own compressor, the failure of one unit will not impact other areas of the facility. This compartmentalization of risk can be crucial for operations where downtime in one area will not affect others.

The initial investment for a separate system may also be lower than for a centralized system, particularly for smaller facilities or those with only a few points of compressed air use, as it avoids the cost of extensive piping. The question of which compressor system is right for you becomes more complex as you weigh these factors. However, managing and maintaining multiple compressors spread across a facility can be more challenging and time-consuming than managing a single, centralized system.

Technicians must travel to different locations to perform routine checks and service, which can lead to increased labor costs and a higher likelihood of overlooked maintenance tasks. The overall energy efficiency can also be lower if the individual compressors are too small or too large or if they operate in less-than-ideal conditions.

Key Factors in Your Decision

Making the right choice between shared and separate compressor systems requires a careful evaluation of several critical factors. Your facility’s specific air demand profile is a primary consideration. A shared system may offer superior efficiency if your operation has a relatively constant and high demand for compressed air across many applications.

Conversely, a separate system might be more effective if your demand is intermittent or varies significantly between different processes, as it allows you to run only the compressors needed at any given time. Your facility’s physical layout also plays a crucial role. In a large, sprawling plant, the long pipe runs required for a shared system could lead to significant pressure drops and energy losses, making a decentralized approach more practical. A centralized system may be perfectly viable in a more compact facility.

Your application’s sensitivity to pressure fluctuations is another important factor. Some processes require a very stable air pressure to function correctly, and a dedicated, point-of-use compressor can often provide this more reliably than a shared system serving many users. You must weigh the cost of installation, including the equipment and the necessary infrastructure, such as piping and electrical work, against the projected long-term operating costs, which include energy consumption and maintenance.

Finally, your plans for future growth should influence your decision. Designed a shared system with expansion in mind, but a separate system might offer more flexibility to add new applications incrementally without needing to overhaul the entire compressed air infrastructure. Choosing the right air compressor machines is fundamental to this whole process.

Reaching a Final Verdict

Ultimately, there is no single answer to the question of which compressor is right for you. The optimal choice depends entirely on a thorough analysis of your unique operational needs, facility characteristics, and financial considerations. A detailed audit of your current and future compressed air requirements, performed by a qualified professional, can provide the data needed to make a well-informed decision.

You can select a system that delivers reliable, efficient performance for years to come by carefully weighing the advantages and disadvantages of each configuration in the context of your specific circumstances. This strategic decision will have a lasting impact on your facility’s productivity and operational costs, making it a critical component of your industrial planning. The best system is the one that aligns most closely with your production goals and provides the necessary support for your operations to run smoothly and without interruption.