Maintenance Tips for Your Two-Stage Air Compressor

Proper maintenance of your air compression equipment ensures reliable operation and extends your investment’s lifespan. Regular maintenance prevents unexpected breakdowns, reduces operating costs, and maintains optimal performance levels throughout the equipment’s service life.

Understanding your equipment’s maintenance requirements allows you to develop a comprehensive care schedule that protects your investment. Two-stage compression systems require specific attention to their unique components and operating characteristics. The dual-stage compression process creates different maintenance needs compared to single-stage units, making targeted care essential for optimal performance.

This comprehensive guide provides detailed maintenance tips for your two-stage air compressor that ensure your equipment operates at peak efficiency. Each maintenance task contributes to your compression system’s reliability and longevity, helping you avoid costly repairs and unexpected downtime.

Understanding Your Two-Stage Compression System

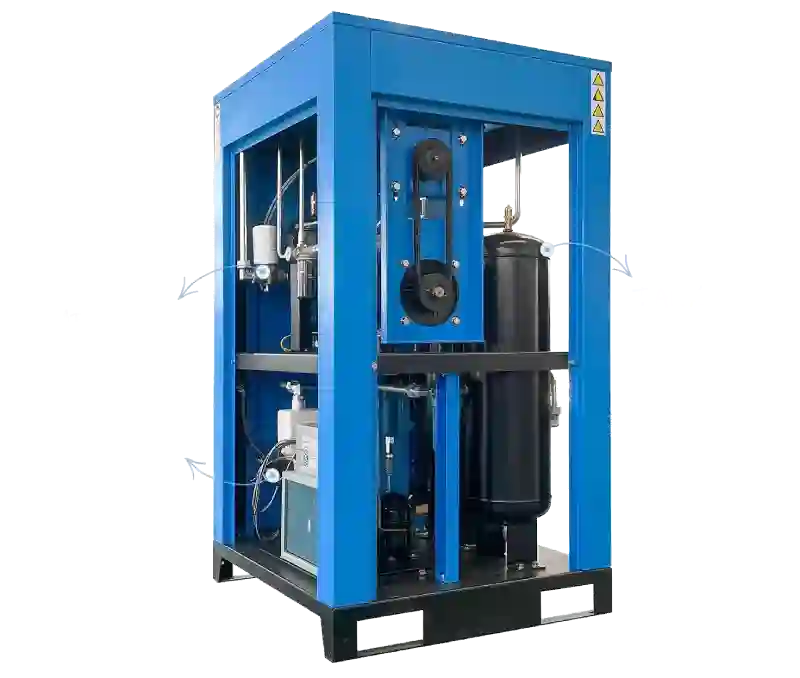

Two-stage compression systems operate through a sophisticated process that compresses air in two distinct phases. The first stage compresses air to an intermediate pressure level, while the second stage completes the compression to the final operating pressure. This design provides superior efficiency and cooler operation compared to single-stage alternatives.

The two-stage compressor design includes multiple components that require regular attention. The intercooler between stages removes heat generated during the first compression phase, improving overall efficiency and reducing wear on second-stage components. Understanding this process can help you recognize the importance of properly maintaining each component.

Regularly inspecting both compression stages ensures optimal performance and identifies potential issues before they become costly problems. Each stage operates under different pressure and temperature conditions, requiring specific maintenance approaches tailored to these operating parameters.

Daily Operating Checks

Daily inspection routines form the foundation of effective maintenance programs. Verify that oil levels meet manufacturer specifications before starting your equipment each day. Low oil levels can cause severe damage to compression components, while overfilling reduces efficiency and may cause operational problems.

Check the air filter condition during daily inspections. Clean air filters ensure proper airflow and protect internal components from contamination. Dirty or clogged filters reduce efficiency and force the system to work harder, increasing wear and energy consumption.

Monitor operating temperatures during startup and throughout the day. Excessive temperatures indicate potential problems with cooling systems, lubrication, or internal wear. Immediately address temperature anomalies to prevent component damage and maintain reliable operation.

Drain moisture from receiver tanks and air lines daily. Accumulated moisture promotes corrosion and contamination throughout the compressed air system. Regularly test automatic drain valves to ensure proper operation and complete moisture removal.

Weekly Maintenance Procedures

Weekly maintenance procedures address components that require regular attention but not daily inspection. Clean the air intake filter thoroughly or replace it according to manufacturer recommendations. Operating environments with high dust levels may require more frequent filter changes to maintain proper airflow.

Inspect all pressure gauges and safety devices weekly. Accurate pressure readings are essential for proper operation and safety. Faulty gauges can lead to improper pressure settings that reduce efficiency or create safety hazards. Test pressure relief valves to ensure they operate correctly at specified pressure levels.

Check belt tension and condition on belt-driven systems. Loose belts reduce efficiency and cause excessive wear on pulleys and belts. Overtightened belts create undue stress on bearings and shafts, leading to premature failure. Proper belt tension ensures efficient power transfer and extends component life.

Examine all electrical connections and control components. Loose connections create resistance that generates heat and reduces electrical efficiency. Clean electrical enclosures and remove dust buildup that can interfere with proper cooling and component operation.

Monthly Comprehensive Inspections

Monthly inspections provide opportunities to examine components that gradually change. Change the engine oil and filter according to the manufacturer’s specifications. Clean oil lubricates moving parts properly and removes contaminants that cause wear and damage. A used oil analysis can reveal internal wear patterns and help you predict maintenance needs.

Inspect intercoolers and aftercoolers for proper operation. Clean cooling fins and remove debris that restricts airflow. Efficient cooling systems prevent overheating and extend component life significantly. Check cooling fan operation and clean or replace fan filters as needed.

Examine all pneumatic and electrical control systems. Test automatic start and stop functions to ensure proper operation. Verify that control settings match operating requirements and adjust as necessary. Properly functioning controls optimize energy usage and prevent unnecessary wear.

Check all safety devices and emergency shutdown systems. Test emergency stop buttons and automatic shutdown functions. Safety systems protect both equipment and personnel, making their proper operation critically important for safe facility operations.

Quarterly Deep Maintenance

Quarterly maintenance addresses components that require thorough inspection and service every three months. Maintenance tips for your two-stage air compressor should include comprehensive valve inspections during quarterly service intervals. Remove and inspect intake and discharge valves for wear, carbon buildup, and proper sealing.

Service the air dryer system if equipped. Replace desiccant materials and inspect dryer components for proper operation. Effective moisture removal protects downstream equipment and ensures compressed air quality meets application requirements.

Perform vibration analysis on rotating components. Excessive vibration indicates bearing wear, misalignment, or other mechanical problems. Early detection through vibration monitoring prevents catastrophic failures and allows scheduled repairs during planned maintenance windows.

Thoroughly inspect and service the electrical motor. Check motor bearings, electrical connections, and insulation resistance. Clean motor cooling vents and ensure proper ventilation around the motor housing. Well-maintained motors operate efficiently and provide years of reliable service.

Annual Major Service Requirements

Annual maintenance procedures address components that require extensive service or replacement on yearly schedules. Perform a complete internal inspection of compression cylinders, pistons, and rings. Measure cylinder wear and replace worn components before they cause secondary damage to other parts.

Service the complete cooling system, including water pumps, radiators, and cooling lines on water-cooled systems. Flush cooling systems and replace coolant according to the manufacturer’s specifications. Proper cooling system maintenance prevents overheating and extends engine life significantly.

Conduct a thorough electrical system inspection and testing. Check motor starter contacts, control relays, and protection devices. Replace worn electrical components before they fail and cause unexpected shutdowns. Document all electrical readings for future reference and trending analysis.

Rebuild or replace major wear components based on inspection results and operating hours. Proactive replacement of wearing parts prevents unexpected failures and maintains system reliability. Schedule major component replacement during planned shutdown periods to minimize operational impact.

Ensuring Long-Term Reliability

Consistent application of these maintenance procedures ensures your compression equipment provides years of reliable service. Proper maintenance protects your investment and maintains the consistent compressed air supply your operations depend on. Regular care prevents minor issues from developing into major problems that require costly repairs and extended downtime.

Document all maintenance activities and component replacements to track equipment condition over time. Detailed maintenance records can help you identify patterns and predict future service needs. This information supports informed decisions about equipment replacement and how to optimize maintenance schedules.

Professional maintenance support ensures complex procedures are performed correctly and safely. Qualified technicians have the expertise and tools necessary to properly maintain your two-stage compressor and identify potential problems before they cause operational disruptions.