Larger Air Compressors vs Multiple Compressors in Series

Selecting the right compressed air system configuration represents a critical decision that affects operational efficiency, maintenance requirements, and long-term costs. Facilities face two primary approaches when designing their compressed air infrastructure: Installing a single larger air compressor or implementing multiple smaller compressors connected in series. Each configuration offers distinct advantages and considerations that directly impact system performance and reliability.

Understanding the fundamental differences between these approaches enables facility managers and engineers to make informed decisions based on their operational requirements. The choice between larger air compressors and multiple compressors in series depends on demand patterns, redundancy needs, energy efficiency goals, maintenance capabilities, and similar factors. This comprehensive analysis examines both configurations to help you determine the optimal solution for your compressed air system.

Understanding Single Large Air Compressor Systems

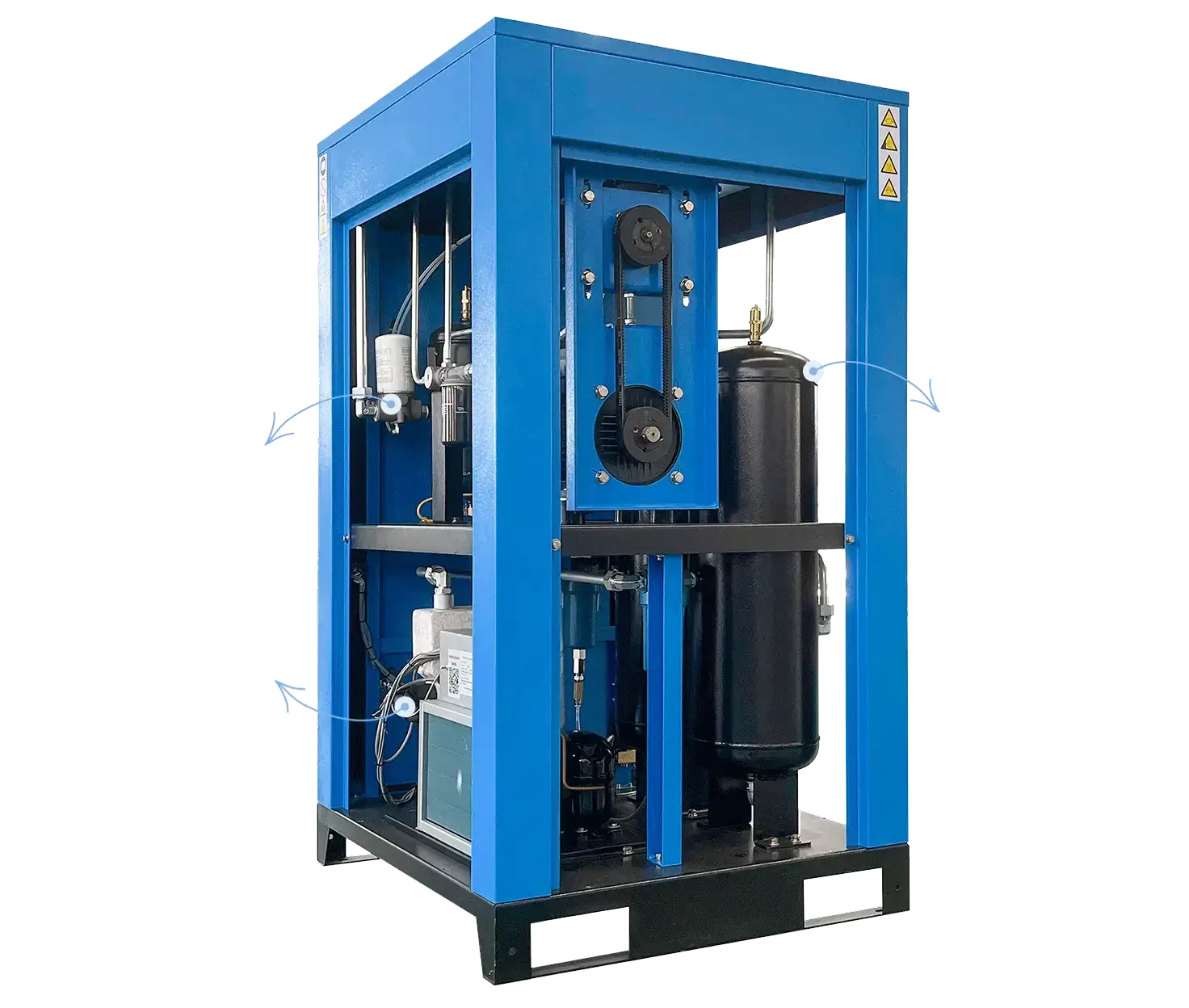

Single large air compressor systems utilize one primary unit to meet the entire facility’s compressed air demand. These systems typically feature high-capacity compressors designed to handle peak loads while maintaining consistent pressure throughout the distribution network. Large compressor units often incorporate advanced control systems that automatically adjust output based on demand fluctuations.

The simplicity of single-unit systems appeals to many facility operators because they require fewer connection points, reduced piping complexity, and centralized control mechanisms. Large compressors frequently offer superior energy efficiency at full load operation compared to smaller units, particularly when equipped with variable frequency drives or advanced load management systems.

Installation requirements for large compressor systems include adequate floor space, proper ventilation, and robust electrical infrastructure capable of handling high startup currents. These units typically require specialized lifting equipment for installation and maintenance procedures due to their substantial weight and size.

Benefits of Large Single Air Compressor Configurations

Large single-compressor systems provide several operational advantages that make them attractive for certain applications. The primary benefit centers on simplified maintenance schedules, as facilities only need to service one unit rather than multiple smaller compressors. This consolidation reduces maintenance complexity and potentially lowers service costs through economies of scale.

Energy efficiency represents another significant advantage of large compressor systems. Properly sized large compressors operating within their optimal range achieve superior efficiency ratings compared to multiple smaller units operating simultaneously. The improved efficiency translates directly into reduced operating costs and lower energy consumption.

Space utilization benefits accompany large compressor installations, as single units typically require less floor space than multiple smaller compressors with equivalent capacity. This space efficiency proves valuable in facilities with limited equipment room availability or high real estate costs.

Understanding Multiple Compressors in Series Configuration

Multiple compressors in a series configuration employ several smaller units working together to meet the facility’s compressed air requirements. This approach distributes the total load across multiple compressors, each contributing to the system’s capacity. The series configuration allows for sophisticated load management strategies where individual compressors cycle on and off based on demand patterns.

Control systems for multiple compressor installations coordinate operation between units to optimize efficiency and ensure adequate pressure maintenance. Advanced controllers can prioritize certain compressors based on efficiency ratings, operating hours, or maintenance schedules. This intelligent management maximizes system reliability while minimizing energy consumption.

The modular nature of multiple compressor systems provides flexibility for future expansion or capacity modifications. Facilities can add additional units as demand grows or temporarily remove units for maintenance without completely shutting down the compressed air supply.

Advantages of Multiple Compressors in Series

Redundancy stands as the primary advantage of multiple compressor configurations. When one unit requires maintenance or experiences operational issues, the remaining compressors continue providing compressed air to maintain facility operations. This redundancy eliminates single points of failure that could halt production or compromise critical processes.

Load matching capabilities represent another significant benefit of multiple compressor systems. You can sequence fixed speed air compressors in series to match varying demand patterns more effectively than a single large unit. During periods of reduced demand, only the necessary compressors operate, while additional units remain on standby, ready to engage when demand increases.

Maintenance scheduling flexibility improves with multiple compressor installations because you can service individual units during planned maintenance windows without affecting compressed air availability. This staggered maintenance approach reduces operational disruptions and allows for more thorough service procedures.

Efficiency Considerations and Load Management

Energy efficiency analysis must consider both peak and partial load operating conditions when comparing these configurations. Large compressors typically achieve optimal efficiency when operating at or near full capacity, but efficiency can decrease significantly during low-demand periods. Multiple smaller compressors offer better part-load efficiency because you can shut units down completely rather than operating at reduced capacity.

Load management strategies differ substantially between single and multiple compressor systems. Single large compressors rely on capacity control methods, such as inlet valve modulation, variable frequency drives, or load and unload cycling. Multiple compressor systems achieve load management through unit sequencing, where compressors start and stop based on system pressure requirements.

Facilities with relatively constant high-demand benefit from large compressor efficiency, while facilities with variable or cyclical demand patterns often achieve better results with multiple smaller units.

Maintenance and Service Requirements

Maintenance requirements vary significantly between single large compressors and multiple compressor configurations. Large compressors typically require specialized service technicians due to their complexity and size. Component replacement procedures often involve heavy lifting equipment and extended downtime periods for major service intervals.

Multiple smaller compressors generally feature more standardized components and service procedures that facility maintenance teams can handle internally. The distributed maintenance approach allows for preventive maintenance scheduling without system shutdown, improving overall availability and reducing emergency service requirements.

Service cost considerations include routine maintenance expenses and major repair costs. While large compressors may have higher individual service costs, the total maintenance burden across multiple smaller units can exceed single-unit expenses when considering labor, parts inventory, and service frequency requirements.

Making the Right Choice for Your Facility

Facility requirements analysis should begin with an accurate demand assessment, including peak loads, average consumption, and demand pattern variations. Facilities with steady high-demand operations and adequate backup systems may benefit from large single-compressor installations. Operations requiring high reliability, variable demand response, or phased expansion capabilities often find multiple compressor systems more suitable.

Budget considerations extend beyond initial equipment costs to include installation expenses, ongoing maintenance costs, energy consumption, and potential impacts of downtime. The total cost of ownership calculation should encompass equipment lifecycle costs, service requirements, and operational efficiency over the expected system lifespan.

Infrastructure requirements, including electrical capacity, floor space, ventilation, and piping considerations, influence the practical feasibility of each configuration. Existing facility constraints may favor one approach over another, regardless of theoretical operational benefits.

Optimizing Your Compressed Air Investment

The decision between larger air compressors vs multiple compressors in series requires careful evaluation of your facility’s specific operational requirements, reliability needs, and long-term growth plans. Single large compressor systems excel in applications requiring maximum efficiency at consistent high loads with simplified maintenance requirements. Multiple compressor configurations provide superior reliability, flexibility, and load-matching capabilities for variable-demand applications.

Professional system design consultation ensures optimal configuration selection based on comprehensive facility analysis, including demand profiling, reliability requirements, and operational constraints. Proper sizing and configuration selection maximize system efficiency, minimize operating costs, and provide a reliable compressed air supply for your facility’s critical operations. Contact qualified compressed air professionals to evaluate your specific requirements and determine the most effective system configuration for your application.