Duty Cycles and Intermittent vs. Constant Operations

Air compressors are the backbone of countless industrial operations, providing the compressed air necessary to power pneumatic tools, machinery, and systems. Understanding how these machines operate under different conditions is crucial for selecting the right equipment and maintaining optimal performance. The operational characteristics of air compressors vary based on their intended use, with some designed for continuous operation, while others excel in intermittent applications.

Duty cycles and intermittent vs. constant operations are fundamental concepts that determine how an air compressor functions within your facility. These operational modes directly impact equipment selection, maintenance requirements, and overall system efficiency. Making the right choice between intermittent and constant operation modes ensures your compressed air system delivers reliable performance while minimizing operational costs and maximizing equipment lifespan.

The distinction between these operational modes becomes particularly important when considering the diverse requirements of modern industrial facilities. Some applications demand steady, uninterrupted compressed air flow, while others require compressed air for specific processes or time periods. Understanding these differences helps managers and engineers make informed decisions that align with their operational requirements and budget constraints.

Understanding Duty Cycles in Air Compressors

Duty cycles are the percentage of time an air compressor operates under load conditions within a given period. This measurement provides insights into how equipment handles sustained operations and determines the appropriate applications for different compressor types. Manufacturers specify duty cycles to communicate the operational limits and capabilities of their equipment.

Air compressor duty cycles typically range from light-duty applications requiring minimal run times to heavy-duty industrial applications demanding continuous operation. Light-duty compressors often feature duty cycles of 25 to 50 percent, meaning they can operate under load for a quarter to half of each operational period. Medium-duty compressors generally handle duty cycles between 50 and 75 percent, while heavy-duty industrial compressors are engineered for duty cycles approaching or reaching 100 percent.

The duty cycle rating directly correlates with the compressor’s cooling system, motor specifications, and overall construction quality. Compressors designed for higher duty cycles incorporate enhanced cooling mechanisms, more robust motors, and superior component materials to withstand extended operational periods. These design considerations ensure reliable performance and prevent premature equipment failure under demanding operational conditions.

Proper duty cycle matching prevents equipment overheating, excessive wear, and unexpected downtime. Operating a compressor beyond its rated duty cycle can result in motor burnout, component failure, and costly repairs. Conversely, selecting equipment with excessive duty cycle capacity for light applications may result in unnecessary capital expenditure and reduced energy efficiency.

Intermittent Operation Characteristics

Intermittent operation is when air compressors cycle on and off based on compressed air demand within the system. These compressors start when system pressure drops below a predetermined setpoint and shut down when pressure reaches the upper limit. This operational mode suits applications with varying compressed air requirements and allows equipment to rest between operational cycles.

Intermittent compressors typically incorporate pressure switches or electronic controllers to manage start-stop cycles automatically. The control system monitors system pressure continuously and activates the compressor motor when additional compressed air is needed. Once the desired pressure level is achieved, the system shuts down the motor until the next demand cycle begins.

The operational efficiency of intermittent systems depends heavily on proper sizing and control configuration. Oversized compressors in intermittent applications may experience frequent short cycling, which reduces equipment lifespan and increases maintenance requirements. Proper sizing encourages adequate run times between cycles while meeting peak demand requirements.

Intermittent operation offers several advantages for facilities with variable compressed air demands. Energy consumption remains proportional to actual usage, reducing operational costs during periods of low demand. Equipment experiences regular cooling periods between cycles, which can extend component lifespan when properly managed. Maintenance requirements often remain manageable due to reduced total operating hours compared to continuous operation systems.

Constant Operation Benefits and Applications

Constant operation air compressors run continuously during operational hours, maintaining steady compressed air production regardless of immediate demand fluctuations. These systems typically incorporate sophisticated control mechanisms to modulate output while maintaining consistent operation. Constant operation suits facilities requiring steady, reliable compressed air supply for critical processes.

Modern constant operation systems often utilize variable speed drive (VSD) technology to adjust compressor output based on real-time demand. This approach maintains continuous operation while optimizing energy consumption and system efficiency. The compressor motor speed adjusts automatically to match compressed air production with facility consumption patterns.

Constant operation provides superior pressure stability compared to intermittent systems. The continuous operation eliminates pressure fluctuations associated with start-stop cycles, ensuring consistent performance for sensitive applications. This stability proves particularly valuable for precision manufacturing processes, automated assembly lines, and applications requiring tight pressure tolerances.

Industrial facilities operating multiple shifts or requiring 24-hour compressed air availability often benefit from constant operation systems. These applications can’t tolerate the brief interruptions associated with compressor startup cycles.

Selecting Between Operational Modes

Choosing between intermittent and constant operation requires careful evaluation of facility requirements, usage patterns, and operational priorities. Facilities with predictable, steady compressed air demands often benefit from constant operation systems. Applications with variable or periodic compressed air requirements may find intermittent operation more cost-effective and efficient.

Application sensitivity also influences operational mode selection. Processes requiring tight pressure tolerances or immediate compressed air responses benefit from constant operation systems. Applications tolerating minor pressure fluctuations and brief supply interruptions may operate effectively with intermittent systems, particularly when combined with adequate receiver tank capacity.

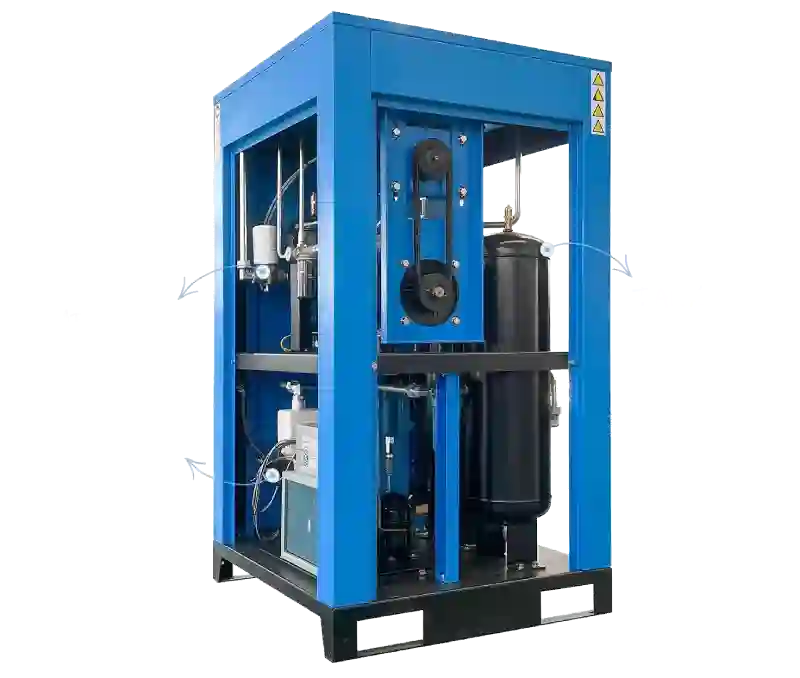

The process of equipment selection for either operational mode should consider the benefits of an all-in-one air compressor system that integrates multiple components within a single package. These comprehensive systems often provide flexibility to operate in either intermittent or constant modes based on facility requirements and operational conditions.

Maintenance Considerations for Different Operational Modes

Intermittent and constant operation systems have distinct maintenance requirements and challenges. Intermittent systems experience frequent motor starts, which can stress electrical components and require regular inspection of contactors, relays, and motor connections. The cycling nature of intermittent operation also subjects mechanical components to repeated thermal expansion and contraction cycles.

Constant operation systems accumulate higher total operating hours, requiring more frequent routine maintenance intervals for filters, lubricants, and wear components. However, the steady operational conditions often result in more predictable maintenance schedules and component replacement intervals. Temperature management becomes critical for constant operation systems to prevent overheating and component degradation.

Both operational modes benefit from comprehensive preventive maintenance programs tailored to their specific operational characteristics. Intermittent systems require careful attention to control components and electrical connections, while constant operation systems demand rigorous monitoring of cooling systems and thermal management components.

Optimizing Performance for Your Application

Duty cycles and whether to use intermittent or constant operations ultimately determine system performance, efficiency, and reliability within your facility. Proper operational mode selection ensures optimal equipment performance while minimizing energy consumption and maintenance requirements. Understanding these concepts enables informed decision-making that aligns compressed air system capabilities with facility requirements.

A professional evaluation of your specific application requirements, usage patterns, and operational priorities will guide you toward appropriate equipment selection and configuration. Consulting with experienced compressed air professionals will identify the optimal balance between operational efficiency, equipment longevity, and total cost of ownership for your facility’s unique requirements.